There is a plethora of home improvement shows demonstrating how easy it is to buy, renovate and flip a house, and make some easy coin in the process. And when there is insulating to be done, it often seems people gravitate towards spray foam insulation. Why is that? Well, it works - at least in some ways.

Spray foam manufacturers’ marketing departments have worked very hard to distract us from the potentially sketchier aspects of spray foam. This has been quite successful, as it has become a very popular insulation choice for renovation projects, and even some new home builds as well.

One angle that is heavily promoted, is the airtightness that can be achieved with spray foam insulation. This has been a great strategy to secure market share as many areas of Canada and the US are adopting more stringent requirements for making homes airtight - but from experience spray foam can age poorly, and shrink or separate - in which case it's no longer airtight.

The advantages of spray foam insulation

When installed properly, spray foam can help make a house airtight (when first applied); it works as a vapor barrier and it adds a significant level of insulation to a home, further reducing the energy needed for heating and cooling. An all-in-one product for home renovation that provides the insulation, air barrier plus vapor barrier is, at least superficially, a very appealing product.

A lot of the discussion we’ve seen online this year is about how good spray foam insulation works, and how ‘sustainable’ it is. The ‘greening’ happened because spray foam manufacturers in Canada were obliged to switch to climate safe blowing agents on January 1, 2021 by the regulatory elimination of HFCs, driven by the Kigali Amendment to the 1987 Montréal Protocol.

This created the perfect opportunity to talk up spray foam as an ‘eco-friendly green insulation’, even though quite a few manufacturers just squeaked into compliance with the new regulations at the very last minute.

We do like to give credit where it's due, and we did write about Demilec's switch to the climate-safe spray foam blowing agents back in 2017. That was well ahead of some other well-known insulation manufacturers who just kept on pumping out the old HFC blowing agents, which were as much as 1,430 times worse in Global Warming Potential.

Global Warming Potential, or GWP, is a measure of how much heat-trapping potential a substance has, compared to carbon. A GWP of 1430 means that a given unit of a substance is that much worse than carbon as a heat trapping gas when released into the atmosphere.

The new HFO (hydrofluoroolefin) blowing agents have a GWP of 1, which basically means that insulating 1,430 houses now with spray foam will do the same atmospheric harm as was done by 1 house in the past. You don't need to be a mathemagenius to know that's a pretty impressive improvement. So we do extend a big thanks at least to Demilec, for being 4 years ahead of the curve.

All the good stuff aside, there are still ecological issues with this 'miracle' multi-purpose insulation product, and we are a bit disturbed to see it gaining such a strong market share in the mainstream building industry without much in-depth discussions or balanced and experienced views about the downsides of spray foam insulation. So....time for a look as the less appealing aspects so we can all make informed decisions.

The disadvantages of spray foam insulation as a green building product

Regardless of the adoption of more eco-friendly spray foam blowing agents, there is still the matters of air quality, building durability and end-of-life disposal of the product itself and anything it touches.

The biggest problem we have with spray foam from a sustainability standpoint, is that it is undeniably made of toxic chemicals, some of which will pollute the indoor air long after owners take occupancy of a home.

And once it is applied to a substrate, it is extremely difficult to remove it. If you do try to reclaim wood or other materials that have been coated with spray foam, it can create a toxic dust in the process which can be very dangerous to those carrying out such work. And aside from just the health risks, simply the cost of trying to salvage spray-foamed materials is the reason they will virtually all end up in a landfill.

Even now while the price of lumber is astronomically high - and so motivation is high to recycle and reuse wood as much as possible - it’s still very difficult to justify the cost of paying someone to scrape foam off a 2x6. So if it isn’t happening now, you know it’s not going to happen when the price of lumber drops back to a more familiar range.

What are the toxic ingredients in spray foam insulation?

The ingredients in spray foam typically include isocyanate and polyol, with a smattering of blowing agent and additives like toxic flame retardants. The polyol, which is mixed with isocyanate to form polyurethane is, in general, a relatively harmless alcohol compound and is primarily added for greenwashing PR reasons as it can be made with soy and other natural oils.

Unfortunately, this tiny amount ( between 2 and 4%) of GMO soy or plant based oil is dwarfed by the toxic soup of other ingredients in SPF wood. But it only takes adding 2% of something non-toxic to justify basing 100% of the marketing around it so people think their homes are insulated with something akin to tofu.

Isocyanate often comes from methylene diphenyl diisocyanate (MDI), and the manufacturing of MDI includes such ingredients as benzene, chlorine compounds and formaldehyde. This combination of chemicals emits a disturbing concoction of dioxins and furans, carcinogens, bio-accumulative toxicants, and endocrine disruptors.

That MDI is one of the chemical ingredients that are mixed on the jobsite which, together, react to create the final spray foam product. Read between the lines here - a freshly trained spray foam installer is suddenly assuming the role of a chemical engineer and spraying stuff in the place you will soon live. That should give anyone cause for concern, as MDI is a known allergen and sensitizing toxicant. Don't just take our word for it, here's what the EPA has to say about the human health implications:

“Diisocyanates are well known dermal and inhalation sensitizers in the workplace and have been documented to cause asthma, lung damage and, in severe cases, fatal reactions."

The really scary part, is that once you have been ‘sensitized’ from exposure to MDI, it can lead to the development of chemical sensitivities, and even the tiniest subsequent exposure in the future can have severe health effects.

The catalyst for the reaction/curing is often an amine compound or lead naphthenate. Amine is derived from ammonia, and can produce the fishy off-gassing smell that is often reported in homes sprayed with this type of foam insulation. The Alliance for the Polyurethanes Industry has this to say:

“Many amine-based compounds can induce histamine liberation, which, in turn, can trigger allergic and other physiological effects, including bronchoconstriction or bronchial asthma and rhinitis."

"Systemic symptoms include headache, nausea, faintness, anxiety, a decrease in blood pressure, tachycardia (rapid heartbeat), itching, erythema (reddening of the skin), urticaria (hives), and facial edema (swelling). Systemic effects (those affecting the body) that are related to the pharmacological action of amines are usually transient. Typically, there are four routes of possible or potential exposure: inhalation, skin contact, eye contact, and ingestion.”

Lead naphthenate may also have effects on the central nervous system and kidneys and it is advised that pregnant women avoid exposure. The National Institute for Occupational Safety and Health (NIOSH), a division of the CDC, states: “It is strongly advised that this substance does not enter the environment."

Spray foam insulation and internal air quality in homes (IAQ)

There's no escaping the fact that spray foam is a petroleum based toxic chemical concoction that is sprayed on the inside of walls, making them not just well insulated, but very airtight as mentioned earlier.

Different manufacturers and installers of spray foam will insist that occupants vacate their homes - anywhere from 24 to 72 hours are the recommendations we’ve seen - to allow the foam to fully cure and off-gas. Are we to assume then, that after that time period - somewhere between 25 and 73 hours - that the human health risks are all gone?

That would be the natural assumption, but rarely would that be the reality in our opinion. In all likelihood, the success of the ‘eco-friendly spray foam’ marketing campaign has led a lot of occupants to re-enter their homes after the allotted time for chemical off-gassing has ended, with the assumption that the air is safe to breath. We find that disturbing.

In reality, what we've been reliably informed of, is that these indicated curing times are what you could expect "under ideal conditions". But even after some digging, we have so far been unable to successfully alleviate our concerns that these ‘ideal conditions’ are always being met.

According to manufacturers, the ‘ideal conditions’ include maintaining the right ambient temperature, suitable humidity levels, and a very specifically-mixed chemical ratio. There is nothing there that makes us comfortable with this, because rarely does anything in on-site construction work out exactly as planned and rarely does it stay on schedule.

We have seen spray foam being applied in wide ranges of temperatures and humidity levels, and none of us have ever heard an installer say they needed to delay their work to protect the future air quality of the home they are spraying. If that were to happen, then pricing would be much higher to account for lost time if installers only worked during ‘ideal conditions’.

Every year there are numerous legal cases involving uncured foam rendering homes uninhabitable making their way through the courts, including this one with over $2.5m damages awarded for "life-altering serious injuries as a result of exposure to chemicals". This home in Canada was made unlivable due to fumes from a spray foam job, forcing residents to spend months living in a camper in their laneway.

Let's assume the best for a moment, and imagine a case where everything worked out perfectly and the foam was mixed and sprayed with the precision of Michelangelo painting the ceiling of the Sistine chapel.

Where, in such ideal conditions, will the toxic chemicals off-gas to? Well, that’s simple. Hopefully some will off-gas to the exterior, but without a doubt much of it will off-gas into the newly built ‘airtight’ home. Let the reality of that sink in for a second.

Where it gets worse, is when you consider where spray foam tends to be used – smaller jobs where the overall cost increase may be more acceptable such as tiny homes, shipping container homes, and basements. Tiny house builders often don’t include ventilation systems, leaving you penned in with your newly sprayed chemicals, and certainly no off-gassing will occur to the outside with metal boxes and concrete basements.

Virtually no air will leak through spray foam after it sets (right after, at least) and as much as we advocate for airtight homes, that can be a very real problem in this case given the risk to health. It is a known fact that indoor air quality in homes can be heavily polluted, and several times more toxic that outdoor air. That’s another stat straight from the EPA.

So, in the scenario of spray foam insulation being added during a renovation - if that's what you decide to use - then at the very least we’d strongly recommend the inclusion of a good HRV or ERV ventilation unit as well, to more quickly bring in fresh air without using excessive energy.

Building houses airtight is great for energy efficiency, but that makes it all the more urgent to protect your home air quality by choosing non-toxic building materials. And given that some spray foam manufacturers have safety manuals as long as 84 pages and multiple hazard data sheets about how to protect yourself against adverse health effects from the chemicals in their "green" spray foam products, we think that’s a good reason to be concerned. Compare that 84-page safety manual to a natural wood finishing oil who’s health instructions recommend ‘not drinking it’ and… “if ingested, seek medical attention, IF you don’t feel well”.

There is a disturbing increase in asthma rates in children, as well as various respiratory issues in people of all ages, and the air quality of our houses is the biggest source of contaminants that we breath.

This was always the case, but it has become an increasingly urgent issue now as many people have adapted to lock downs and working from home. So more renovations are happening, and people are spending far more time at home now, and many are building offices to work from home either full or part time moving into the future.

Is spray foam insulation really airtight?

Yes, spray foam seems to be airtight after it has set. But will it stay that way? That’s not as clear. Spray foam insulation is a liquid that adheres to surfaces (wood-framed walls as the common example), then expands and hardens. One thing it is not known for, is flexibility. And one thing that all buildings will need, is a little flexibility. Houses move; end of story.

Concrete expands and contracts, it heaves and cracks, and there is nothing you can do to stop that. You can reduce the severity of the impacts, but forever at some minor level, concrete will move. And if concrete moves and shifts, then you know for sure the wood walls that sit on it will be moving and shifting too. They don’t move a lot, or even noticeably, but minor ground shifting and wind pressure exert enough pressure on buildings that a lack of material flexibility can lead to reduced efficiency and durability.

How air leaks through spray foam

Wood studs arriving on a construction site are almost always wet, and they are usually left out in the rain until needed. So if they weren’t wet at first, they will be soon enough. Framed house walls will also spend weeks or more standing in the rain getting saturated with moisture before exterior weather barriers and roofs protect them from the elements.

That means spray foam is applied to wood framing members with absolutely no consideration of the moisture levels of the wood. And what happens when wood dries? Well, it shrinks. And what happens if something solid is stuck to it isn’t flexible? Well, it cracks.

We have no doubt that in the beginning when all the chemicals are off-gassing from the foam into your house, that the foam is airtight enough to keep the toxins inside while it off-gasses, but as the months and years pass and the wood dries and cracks, will it retain its original airtightness? Not likely in our humble opinion.

We are fully aware that no house is perfectly airtight, but the more adaptable (flexible) a product is, the more chance it will withstand the normal movements that happen in buildings, which most people are not aware is even happening.

Is spray foam recyclable?

Currently, not really no. I’m sure someone somewhere has come up with a creative use for old bits of spray foam, but for the most part it will be heading to a landfill at the end of its life. Wood studs are recyclable, plywood is recyclable, rigid foam insulation boards like EPS are recyclable and even reusable, but anything with spray foam stuck to it is in all likelihood going to the dump. That means any wood, concrete or plastics that it is adhered to that could have been useful will fill up a landfill.

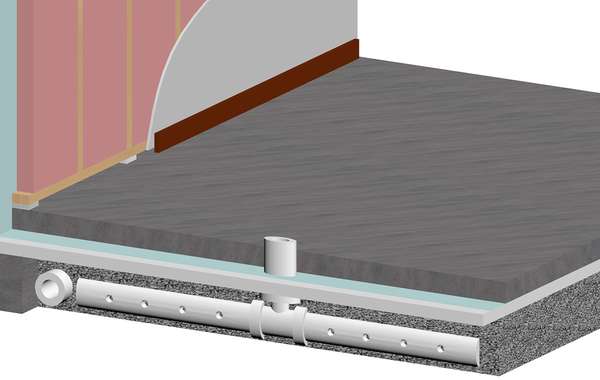

So what is our conclusion on spray foam? It is, on one hand, a great product for certain precise applications. That would include insulating rim joist cavities in basements or small individual uses on a case-by-case basis. But on the whole, it is very difficult for us to consider this in anyway a green building product, even considering the new blowing agents. We conclude that partly because of the potential for air leakage through long-term shrinking, but mostly because of the potential health effects from chemical exposure, and the fact that the final destination for anything it touches is in all likelyhood, the dump.

The key to any successful build begins with thoughtful design and building material selection. Right on the heels of that as a priority, is choosing a higher quality and competent builder. See our page here on how to find green home building general contractor, because they aren’t all the same. Some will cut corners, some will not. And that, is the premise of this article. There are aspects to building with spray foam that make the consequences of taking short cuts riskier than with other insulation, air and vapor barrier materials.

We would strongly recommend that if you are considering insulating your home with spray foam that you use a professional installer and resist the temptation to try the DIY spray foam kits - and carefully vet professional spray foam installers. Ask for references, ask about installer training, and ask how aware they are of the dangers. If they dismiss your concerns and tell you it’s perfectly safe, then you know they don’t take it seriously so hang up and call someone else.

Now you know more about spray foam insulation and its impact on indoor air quality and landfills. Find more pages about sustainable construction below and in the EcoHome Green Building Guide pages.

Find more about green home construction and discover the benefits of a free Ecohome Network Membership here. |

This article raises a number of points in very generic terms without context. A typical approach used when one is writting a narrative with a foregone bias arleady established. So as one who is active in the spray foam industry in the Canadian Market, I would like to clarify some inaccuracies here. 1) as a point of clarification, there are two types of foam typically used in construction that are a catagorized by density. Half pound open cell SPF and Two pound closed cell SPF that have the physical blowing agent (HFC or HFO) as noted here. In Canada all foam systems that wish to enter the market for sale must be tested by independend third party accredited laboratories in order to prove their physical properties meet established ULC standards of benchmarked performance charatcteristics of the cured final product. These include air permeance, vapour permience, compressive strength, tensile strength, off-gassing of VOC's, and many other elements. Millions of lbs. of foam are installed each year in homes around the globe. It is generally specified by architects due to its ability to provide high thermal resistance per inch, an integral vapour and air barrier material, AND the high compressive strength that can increase building rack and sheer performance as well as truss uplift resistance by up to 400%. All of the performances claimed have been rigorously tested over the years. CUFCA in Canada has lead the testing field of spray foam for the past 37 years and we publish our research reports on our website for access by design professionals. To only look at one metric of a material does it a disservice. It is not just the airtightness but the combination of all of it's performances which are typically superior to its market competitors that make it such an outstanding product choice.

1) Yes it is largely petroleum based chemicals that require it to be handled by trained and licensed professionals ( in Canada at least). We do not advocate it be sold to or installed by homeowners as a DYI product lacking the necesary PPE.

2) Yes end of life recycling remains challenging due to the very properties that make it an excellent air barrier and structural member. But lets keep in mind the life horizon of homes that we build. Occupancy could and should perhaps be measured in 75-100 years or more. The reduction in carbon use due to performance gains should be a defensible rationale dispite the end of use disposal means currently available.

3) As with all trades, there will be some examples of poor intallations. But given the size of the annual market of 2 lb. Closed Cell SPF worldwide, the examples often referenced are few and far between. Yes, it is unfortunate that bad workmanship occurs to any homeowner. But we would suggest that the amount of happy homeowners that have sprayfoam installed correctly by property trained and licensed Contractors would be the vast majority.

Hi Andrew.

Thank you for taking the time to share your thoughts. You mention a "narrative with a forgone bias already established"; let’s look at that for a second - Ecohome is a building information website for North America with no skin in the game, and whose mission is to provide homeowners and builders with pertinent information to help them make sensible choices that lead to healthier and more efficient homes with reduced environmental impacts. The Canadian Urethane Foam Contractors Association on the other hand, that you mention, describes themselves as "the national association [for Canada] actively promoting the NUMBER ONE insulation product - spray-applied polyurethane foam.”

The information we provided above that you take issue with comes from the National Institute for Occupational Safety and Health (NIOSH), The Environmental Protection Agency (EPA), and spray foam manufacturers own safety data sheets for the plentiful quantities of DIY kits available for purchase across North America - either online or in local hardware stores, including Canada.

As for the three concessions you made that absolutely align with the article, you acknowledge that:

Those three issues were the very premise of this article, so thank you for corroborating them. As for your statement that "Millions of lbs. of foam are installed each year in homes around the globe" – perhaps true, but quantity does not equate to quality, it just makes the dangers exponentially worse the more people use it. The USA also used to use 800, 000 tons of asbestos every year, they have since decided that the health risks outweigh the benefits.

And regarding the risks associated with DIY spray foam applications, you say “We do not advocate it be sold to or installed by homeowners as a DIY product”, yet the shelves are full of such products and the internet is full of DIY spray foam instructional videos. Here is a quote from one particularly disturbing DIY spray foam video discussing the importance of mixing chemicals properly, viewed more than 3 million times -

“If you get a wrong mixture, sometimes you’ll get a clogged line or something, so if you get too much of one of the chemicals, and I can’t remember which way it is, you’ll actually get soft mushy foam. And if it goes the other way where the other chemical is too much, the foam is really brittle”.

As the national body representing this industry, we wonder whether the CUFCA has taken any action to educate Canadians and warn them of the serious health risks they could be exposed to from untrained installers or DIY installations? Has there been a public safety warning issued on their website or elsewhere? Even here as we are making such warnings, you acknowledge our points but actively downplay the risks to human health and accuse us of bias at the same time. We will leave it to our informed readers to decide where any bias may lie.

Here is a short clip from one of the countless training videos that are out there and that causes us great concern. If it does for you as well, perhaps you’d consider working with us to warn people of the dangers of following such advice?

This article is so misleading and very biased

We would be happy to hear your reasoning, and if you are involved in the spray foam industry please let us know what you do.

I wouldn't say Ecohome has "no skin in the game", your Offical Partner listed at the end of this article is Owens-Corning, a fiberglass batt manufacturer.

Nic - We have many insulation partners that produce insulation out of a variety of materials, and have had many others over the years, including companies that offer spray foam as part of the products they offer. We don't alter our content to suit any manufacturers and we don't display products we find to be among the more ecologically harmful.

Thanks for this, guys. I'm a bit disappointed that in code-conventional construction we're back to tucking batts around that pesky wiring and plumbing, but I'm no longer on the fence about spray foam. Another cause for concern: someone has to make the chemicals, mix them, transport them and retail them. There's unacceptible potential for mishaps (spills, exposure) for workers at each stage. I'm assuming you hold the same opinion of the new air sealing tech for new building like AeroBarrier?

whoops! Just found this https://www.ecohome.net/guides/3364/aerobarrier-home-air-sealing-spray/

Hey Gary, thanks for the comment. I know what you mean about packing insulation around boxes, but I never found it to be that much more labour intensive, and I hated working with spray foam in all but very necessary cases. We always liked Rockwool for that since its so easy to cut and always left a clean job. These sample pics are from an interior soundproofing how-to video, so you can see how easy it cuts. I'd way rather do this than spending a week waiting for spray foam to wear off, as it virtually becomes part of your skin if you get it on you.

As for Aerobarrier air barrier spray - it doesn't have the same health risks from off gasing, so in that respect its not a concern to us, nor is there anywhere close to the volume of material being used in terms of raw materials. Aerobarrier spray is applied by pressurizing a house and filling the air it with tiny droplets that adhere to small openings to seal them. It only adheres where there is a hole and air escaping, so I don't know that you'd even see the stuff on a 2x6 during a house decomissioning decades later. So it wouldn't affect the future recyclability of materials.

Note - I would stay equally far away when its happening, but since it is only filling the tiniest of cracks or holes in an air barrier rather than *being* the air barrier like spray foam, the actual volume of material you are left with afterwards could perhaps be just a handful or two of 'actual' material. So even if it were toxic, any off gasing from the product left behind would hardly be a drop in the bucket compared to an entire house coated inches deep with spray foam. Thanks for bringing that up!

And to your other points - you're bang on about the chemicals. Yes, they need to be manufactured and transported, and yes mishaps do happen. I would rather hear a truck carrying batt insulation tipped over and dumped it's contents in front of my house rather than a truck carrying spray foam chemicals.

As mentioned in the article, there are places where even we feel spray foam is the right thing to use, but there aren't a lot of such cases so we're glad you're off the fence :)

nice

I found this article and the comments from both sides of the aisle here very helpful to read. If this is still an active forum may i ask a few questions to any kind soul who might answer. I have a unfinished second story on my home and the first floor has been finished and insulated with roll in insulation for nearly 3 decades. The second story is a beaufitul waulted ceiling with teo large dormers, about 900sqft. I myself try to avoid everything toxic i can and practice moderation in all aspects. Right now to avoid lowering the ceiling and get a tighter seal on the home due to in adequate A/C and heat that will not potentionally be taken care of for multiple years when an addition is done which includes second A/C and furnace for the new expanded second story. RIght now i'm leaning towards 3" Closed cell on my vaulted ceilings, 2" on the dormers, and tradtional insulaiton in knee walls and the two main walls under the gables at each end. ONE very importantly due to being torn down a the addition date to add on to the home.

1) will my homes combination of closed cell and tradtional insulation protect me from some of the "air tight" problems a complete closed cell foam home can have including the off-gas?

2) are there alternative to put in a ceiling with 6-8in rafters i don't want to bring down farther?

3) IF installed correctly by proffesionals will my installation hypothecticall be adequately "safe"

4) what question do i ask to confirm this CCSF is the new variety? and i understand tha new variety has 1400 times less impact on Global warming but is the end product actually safer for my family?

5) this space will be a open concept master suite, myself and my partner will spend all our nights and many other countless hours here. Is this really the right path forward?

I was actually suprised from a large installer in my area quoting a rate under what i expected and they seemed quite proffesional... Is getting them to garauntee a safe instalation enough?

Thank you for anyone taking the time to respond.

I am a registered General Contractor in the state of Washington. I found this article and the comments helpful and informative overall. I am starting a renovation on a home I purchased that was built in 1933. The wall cavities are currently empty. I am considerinf a variety of products including spray foam. Is there a green "drill and fill" alternstive anyone would recommend? Thanks! In community, Joy

Hi Joy, have you thought of using cellulose? Here is an article about dense packed cellulose in walls. In the older days it used to settle over time and leave the top portions of walls uninsulated, but in modern times with being blown into walls very densely it doesn't settle. Hope this helps!

My goal is to have small size, passive home build that is made with as little environmental impact as possible and not contributing Planetary Boundaries breaching. Spray foam, when looking at it from this point of view is a large negative for the planet.

Interesting article, however, it does not talk about the greater thermal performance, high R-values, structural strength, etc. of spray foam insulation. Being a Toronto spray foam installation expert, I understand that it is majorly of petroleum-based chemicals and that is why in Canada it is handled by well-trained and licensed professional spray form insulation experts. Poor installations cause issues however when done properly by professionals the benefits are a lot.

I think those points about spray foam have been covered pretty well by industry marketing wouldn't you say Kanica? That's all we hear about spray foam from manufacturers, and the mere mention of health risks has pros like yourself trying to turn the topic back to all the good stuff.

Other forms of insuation that are not installed properly don't come with dangerous health risks or make homes uninhabitable, so it would be nice to hear the industry own some of those realities and mention it to their clients. What warnings do you give your clients about the potential negative impacts to the air quality in their homes after installation?

They probably give the same warnings as tabacco companies do, meaning nothing, unless forced by the governments to do so. A nationwide class action lawsuit has been launched by two homeowners against NCFI Polyurethanes and McGlaughlin Spray Foam Insulation Inc. alleging they manufactured and installed toxic insulation that can harm property and cause adverse health problems.

https://topclassactions.com/lawsuit-settlements/lawsuit-news/homeowners-file-class-action-lawsuit-over-toxic-spf-insulation/#:~:text=A%20nationwide%20class%20action%20lawsuit,and%20cause%20adverse%20health%20problems.

Great Post, Thanks for Sharing.

Thanks David. Sorry I had to remove the link to your spray foam website, we don't allow those in comments. Nice to hear agreement from an industry professional and thanks for taking the time to write.

Thanks for this informative article. We are looking to reduce heat loss in our unfinished basement (1920s house) and considering having HFO sprayed directly onto the thick concrete basement walls. I am concerend about some of the cons of using spray foam that were raised in the article. I was considering rockwool comfortboard (attached directly to the concrete walls) as an alternative, but not sure whether this could lead to moisture problems with moisture leaking through the concrete walls and being retained by the comfortboard. We can get moisture in the spring and summer when humidity is high and run a dehumidifier during this time. We are not planning to frame the walls at all, so didn't want to combine with framing and batts. Would this be a viable alternative to using spray foam in this sitution? Are there any others? Thanks for any advice you can provide.

I just bought a new build and I don't think I have a choice but to get what they give: spray foam. I haven't had a chance to question them on the installer or other particular. I did read about Icynene and was surprised it wasn't mentioned in this article, unless that is what is being referred to by the "better stuff" that really isn't that much better? Please comment.

It says official partner of the fiberglass advertisement below. As far as the article goes, just hire professionals and every issue listed above is no longer a issue. Fiberglass insulation is a absolute enormous industry with hundreds of millions spent or shelled out to Fiberglass lobbyist each year. This is just another example. Trying to scare people away from spray foam insulation with scare tactics and scenarios that can happen if the contractor/homeowner try to save or pocket money by going with a low bid. The low bid is almost always low because of lack of experience or they low bidder already knows that he is about to screw you over. My point is, if you go with the low bid and don't do research on who is spraying the foam insulation in your project then you are most likely headed for trouble. There is no reason to try and scare the sense of of people. Anything out here in the world today is or can be dangerous if not properly executed. No matter how hard or how much money fiberglass lobbiest throw at it, spray foam is going to take it's place. It's called progress.

That's funny, spray foam will remain an option for homeowners for the foreseeable future, but it will never take the place of fiberglass insulation or cellulose, more and more people in the USA are choosing other options Vs spray foam, we're seeing legal advertising for people who have been exposed to toxic chemicals from spray foam.

Excellent info!

As in most areas of home remodeling/construction, this is not a one size fits all decision. Indoor air quality is a serious issue in most homes/indoor areas due to a variety of reasons - with inorganic materials at the top of the list. Yet, we also need better-insulated homes, which trap inorganic material.

Each application is different and this article gives many great suggestions on how to make the best choices.

We had a spray foam nightmare occurr in our home last November in the basement. It did not cure correctly and we have not been able to live there. We are looking for advice on how to clean our home in order to move back in. What cleaning products are needed to clean walls, ceilings, floors, furniture, etc? Are there companies available who clean homes due to spray foam errors?Any advice would be greatly appreciated.

How about under a basement slab, is Polyurethane potentially dangerous still?

Hi Ronald, to step entirely away from the health or environmental issues for a moment, simpy the execution of that would be an unnecessary and expensive complication for slab insulation. Flat sheets of EPS are as inexpensive as foam gets and can be laid down in a fraction of the time by anyone. And EPS provides a flat surface on top rather than the uneven surface you would get from spray foam, so I'm not sure what benefit there would be. The only thing would be if you're looking to upgrade the R value of your slab, in which case you would be far better off to just add a bit more EPS foam.

Currently, my slab is uneven, done by amateurs, myself and some helpers.

I own a 170 year old Victorian with a stone foundation in New England. My plan (before reading all of the above) was to have the stone foundation walls and the space inside the sill "spray- foamed." The beauty of my plan was that the foam will also cut way down on basement moisture in the basement in summer, as well as insulate our living spaces above. I went on line to get expert info about how long my tenants and my family REALLY need to stay out of the house, after one the spray foam installers told me that it's ok after a few hours. Most have told me 24 hours. Now I'm seeing 72 hours. And of course I'm more worried than ever about what I am doing to all of us living here by putting a poison permanently in the basement. I also wanted to find out how soon after application I should sheet rock, thinking that would contain some of the off-gassing, though now that seems ridiculous; it's a gas for heaven's sake.

Really, I don't know what to do. Rock wool or cellulose will all collect moisture. I went way out of my way to pour roll out DMX over the entire 1200 sq ft basement to help move ground moisture over to the foundation walls and out. All that effiort was wasted if I can't I find a moisture barrier for the stone foundation.

I think I'll just hope that someone invents the perfect solution this winter so I'll be able to proceed in May!

Do you have any experience with HandiFoam? I'm still learning about it, but it looks like it uses a low GWP blowing agent and it's Greenguard Gold cerified. I'm asking because I was hoping to use it, though this article gives me pause.

Hi Jeffrey, that product seems to be similar to other brands of small cans of spray foam used for isolated use as a gap filler and sealer, and really the article is about doing entire homes in spray foam where the chemicals are mixed on site often by untrained installers. There are places where spray foam makes a lot of sense, so if you're not chemically sensitive and looking to fill gaps and cracks, I wouldn't be too worried about proceeding with your original plan.

Hey guys,

Thanks for the very informing article. I was literally about to specify spray foam for a green home remodel for my parents who are planning to age in place. I already had a bad feeling thinking of a tightly sealed home with spray foam off gassing inside the home as they watch TV and relax. Something about this wasn't sitting well.

I am doing a total180 now to find more green alternatives for attic insulation. Any recommendations would be apprecaited.

Thanks again,

Chris

Hi Chris

For attics it is really easy to do blown in cellulose, or even blown fiberglass. Either gives you a thick seamless blanket, but obviously it doesn't have any air barrier characteristics as can be the case with foam, so you just need to have 'air barrier' on your radar.

If you do go with blown in insulation, or batts if that ends up being the case, be sure to have baffles in the attic to keep soffit vents flowing to remove moisture. Take a look at this page about how to ventilate an attic properly, it may have some value for you.

Thanks for this article. I have a few questions, and apologies if some of these were covered in the comments. I'm about to start a renovation project of an old cabin and the insulation is the last decision I need to make before the contractor gets started. Honestly, it's driving me crazy. My architect proposed a deep energy retrofit approach for the walls, which would include fiberglass batts between teh studs and continuous polyiso outside to prevent bridging. The roof and basement of the existing cabin would be spray foam. The contractor, however, like all contractors in teh area, is really resistant to the polyiso approach, claiming it will be far more expensive than closed-cell foam (due to needing to build out the walls and thus the windows, etc) and that "nobody does it that way up here." It also appears that he's never done it any other way, so there's resistance coming from his lack of experience. The spray foam company itself, which seems to be fairly reputable, claims its materials are "non-toxic;" they (and another architect in teh area) claimed that it stops off-gassing after 30 days and is relative safe "now that it doesn't contain formaldehyde."

So a few questions: 1) is the claim about formaldehyde true? It seems that it isn't, since all foam seems to still be made with MDI; 2) Is it better to have spray foam in the basement and attic than the walls in terms of protecting from off-gassing? Seems like if the basement and attic are airtight, the stack will be minimized, helping to keep those chemicals out of the living areas. I might need to make a comrpomise there; 3) Any tips on convincing recalcitrant contractors to do things the right way?

Thanks a bunch.