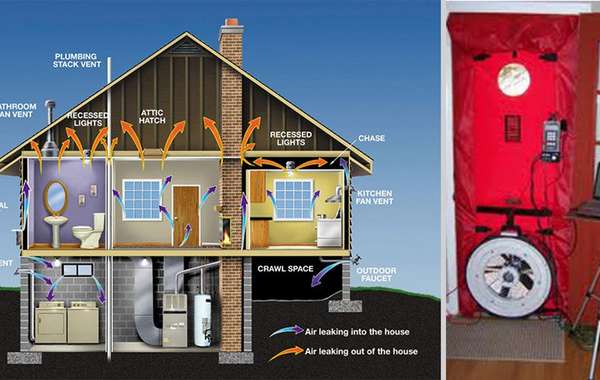

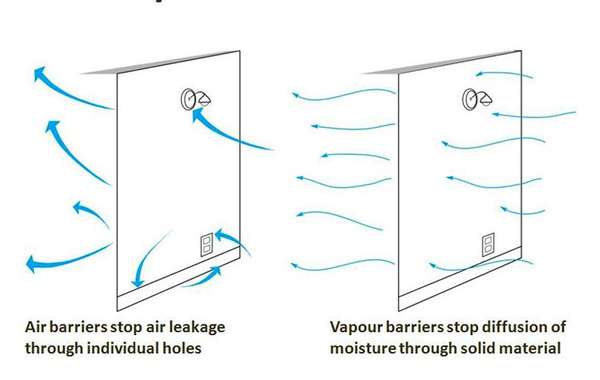

We cannot overstate the importance of airtightness in homes and attic rooms. A proper air barrier reduces heat loss in winter, overheating in summer, and prevents moisture build up in walls which can lead to mould and rot.

We recently had a chance to try out a product that at first sounds too good to be true, but one that actually lives up to its reputation. We consider this new technique to be an industry game-changer for building airtight homes, and it is extremely rare that we offer a product or technique such accolades.

For more than 20 years, Aeroseal has been using an air-sealing technique for ventilation systems where adhesive fine particles are sprayed into ducts, leaving the ducts perfectly sealed. Based on the success of that procedure, the company created the product Aerobarrier, which can seal entire homes.

How Aerobarrier works:

Using standard blower-door testing equipment, a house is pressurized to between 50 and 100 Pascals. Aerosol nozzles are placed through the home which then spray Aerobarrier water-based liquid acrylic sealant. The elastic particles in Aerobarrier are non-toxic and low in VOCs; they also carry GreenGuard Gold & UL181 certifications.

As the air pressure carries particles towards any breach in the building envelope, they begin to adhere to the sides of that opening, gradually sealing the hole. An air seal is thereby created around any openings and cracks in ceilings, walls, windows, plumbing and electrical penetrations. This is an easy way to plug holes in your air barrier that you can’t possibly see - from as small as a human hair to as big as a half-inch wide.

The airflow in the home is monitored in real time by the blower door computer. Depending on the building size, the number of leaks and the client’s desired level of airtightness, the process of installing Aerobarrier in your home or attic room can take from 1 to several hours.

Salvatore Ciarlo, Director of Technical Services, National Codes and Standards, at Owens Corning Canada, tested the product on seven new homes under construction and relayed the following results: "On average, the process took less than an hour and a half. Houses that at first had ratings of 2 air changes per hour (ACH) were brought to as low as 0.39, exceeding Passive House requirements, which are 0.6 ACH.”

We tested Aerobarrier ourselves:

Ecohome’s French counterpart Écohabitation is in the process of moving to new office space in an older building, and when a blower door test was performed during renovations, a very leaky rate of 8.1 ACH was recorded.

This presented an opportunity to test Aerobarrier that looked so promising. After two hours of spraying, the ACH stagnated at 3.8 CAH50. Patrick Rouleau, Director of Sales and Marketing at Aerobarrier Global, who was there to supervise the project, stopped the process at that point to thoroughly inspect the premises with his team.

"We found several openings greater than 1 inch in diameter; there was no polyethylene barrier on the ceiling and insulation was improperly compressed in some places, leading to openings beyond the ability of the particles to fill. We are confident that once minor anomalies are manually sealed, the CAH50 rate should be less than one inch."

Air-sealing with Aerobarrier for renovations:

This is a relatively simple solution to air sealing an old home that is being put through an extensive energy retrofit, where leaks can be extensive and inaccessible. The house first needs to be prepped and treated in the same way as you would for a spray-painting job therefore there would be more extensive preparations for renovation work than with a new home.

All penetrations you don’t wish to fill, such as bathroom fans, stove hoods, shower drains, dryer vents, etc., must be well-sealed before the work is performed. But as old homes often have very high air leakage rates, the added effort required to install Aerobarrier will often pay for itself in short order through energy savings that would be impossible to achieve through conventional air-sealing techniques.

According to Patrick Rouleau, "this is a great technique for someone who wants to improve the energy efficiency of their home. The important thing is for the customer to contact us as soon as possible so that we can together determine the appropriate time to perform the work. For major renovations, that would be once the drywall is installed but before the furniture is brought back in”.

Aerobarrier works with any type of wall assembly, and with new homes it can be done at any stage once the envelope has been closed in and is ready to be pressurized. That can be before batts are installed if you are doing an exterior air barrier, or you can wait until the drywall is completely installed and mudded.

Another advantage of this product is realized with multi-unit buildings as it seals off individual units; the transmission of odours between units from cooking or cigarette smoke is greatly reduced.

How well does Aerobarrier cleanup?

This was a concern of mine the moment I first heard of it, as I imagined all surfaces in a home coated in some sort of Teflon-type material, but as surprising as it is, that simply doesn’t happen. There is a first phase change as Aerobarrier goes from a liquid to being sprayed out as a fog within the home, then another as it solidifies. But that only happens when there is an acceleration, as the air pressure in the home carries it towards and through a hole.

What Aerobarrier doesn’t do, is stick to any vertical surface. You would for sure not want it falling on exposed furniture, but there will be no slimy film that needs to be scraped off of windows or walls, as would be a natural assumption.

Saving time and money

This air-sealing process saves valuable labour-hours for builders and renovators who target higher than normal standards of efficiency; successfully applying sealants, tapes and gaskets is time consuming, and materials can cost a small fortune.

The company doesn’t like to give any false impression on price, as there are too many variables to be able to do that accurately. But to give a reasonable ballpark cost, according to Patrick Rouleau, "we are talking about a likely range of between $1.75 and $ 4.00 per square foot, depending on the building size and level of air changes. It will also fluctuate based on temperature and humidity levels, which will influence the setting time of the product”.

The company originated in California but is spreading quickly across the US and Canada and is "As Seen on" This Old House on episode 3808. Check the Aerobarrier dealer locator on their website to find out if there is a contractor in your area.

Energy efficiency is one of the easiest and most cost-effective ways to combat climate change, clean the air we breathe, improve the competitiveness of our businesses and reduce energy costs for consumers.