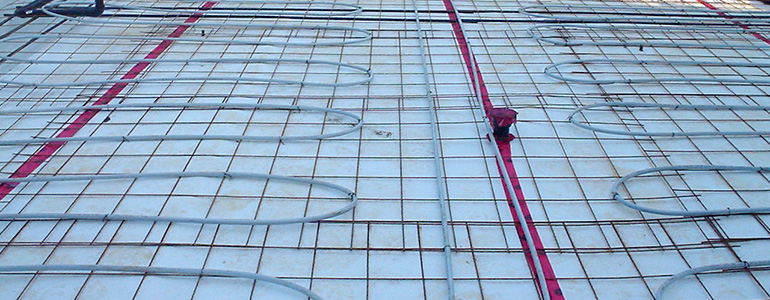

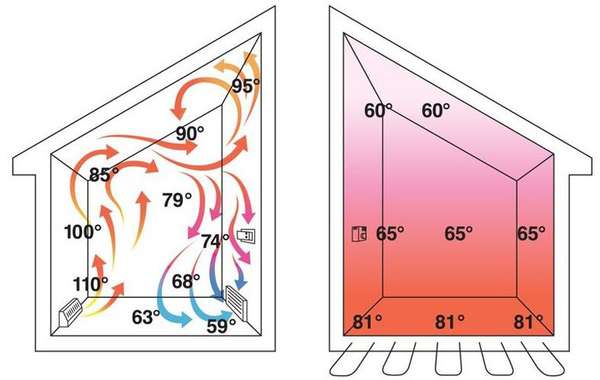

Radiant heating systems are very common in concrete floors now because they provide a very balanced and comfortable distribution of heat. Those systems are most commonly hydronic, meaning heated liquid is pumped through tubing in the concrete which then radiates that heat into the house. View the slab on grade foam forms installation video here.

|

|

Hydronic radiant tubing for a slab-on-grade floor © Ecohome

|

You can see a Video Guide on How to Install Hydronic Radiant Heated Floor Tubing HERE

Alternatively, you can heat floors with electric wires and this is often the most affordable after-market solution for happier feet. Even in new homes with forced-air heating, electrically-heated mats are sometimes installed below the tiles in bathroom floors for added comfort. What you don’t see a lot of, are floors heated with air.

|

|

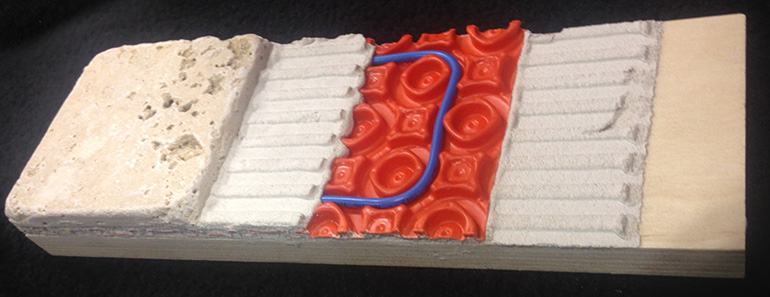

Electric wire radiant floor heating © Ecohome

|

How to make air-heated floors work:

Since the first forced-air heating systems were introduced into homes, there have been attempts to distribute that heat through flooring systems, but they often failed miserably. The most problematic of those were attempts to heat concrete floors with standard metal ducts from forced-air furnaces.

|

|

Collapsed duct © Inspectapedia

|

Embedding ducts in concrete that were not intended to bear weight frequently caused them to collapse, rendering the heating system completely ineffective. Ducts that didn’t collapse were at risk of filling with water or at the very least, moisture. This led to corrosion and blockages, so even systems that worked at first were at risk of a short functional lifespan.

|

|

Corroded duct © Inspectapedia

|

For the systems that did work, and during the time they were working, they would have offered at least some success in warming floors, but doing so brought air quality concerns. These makeshift floor-heating systems functioned similarly to any other forced-air ducted system, where air from the home was circulated through heat vents and cold air returns.

Circulating air from the home though these floor ducts led to the normal dust and debris that can be found in any home being deposited in these floor ducts, and overtime created a buildup of organic matter.

|

|

Corroded vent image via Inspectapedia

|

In summertime when systems were inactive, dust-filled ducts embedded in cool, humid concrete floors provided the ideal environment for mold to develop. In the fall when systems were activated again, air circulating through dirty and moldy ductwork would distribute particulate and mold spores throughout the home. For Information about the importance of air quality in the home and how to improve it with ERV & HRV Ventilation systems see HERE.

During inspections with remotely operated cameras, some even less appealing discoveries were made, including snakes, insects, dead rodents and their excrement. If you really want to, you can read more about that here.

How these flaws can be remedied:

- Make it a sealed, closed-loop system so that air in the heating system is not exchanged with the air of the house.

- Install non-corrosive duct work.

- Cure the concrete to remove moisture before systems are activated.

A company called Legalett that originated decades ago in Sweden now manufactures and distributes heated-floor systems across North America (you can get a quote here). They are the only company we know of that provides this system; if anyone knows of others, please let us know in the comments section at the bottom.

Why the Legalett radiant floor system works:

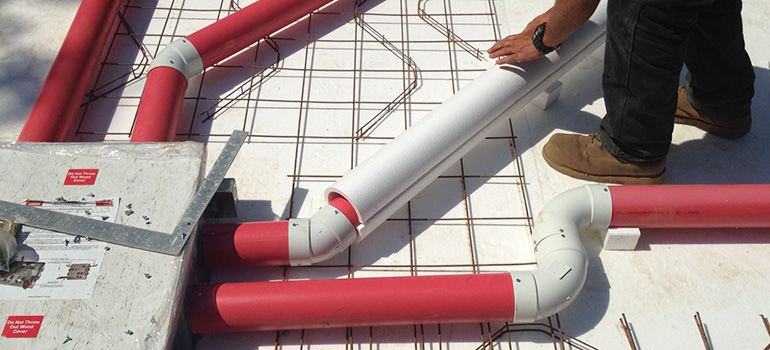

Legalett air-heated radiant floor heating systems are entirely embedded in concrete, including the heater box. It is a closed-loop system where air is moved through either 2 or 4-inch PVC tubes (which are non-corrosive), so that no dust from the air in the home is introduced into the system. There are no open vents, so there is no access point for rodents and insects.

After the concrete is poured, Legalett requires floors to be cured with an open-air construction heater (provided with the system) that maintains a temperature of 28°C for 3 weeks before permanent heating units are installed. This acts to remove moisture from the concrete and prevent corrosion of metal components in the heater box.

Advantages of air-heated radiant floors over hydronic:

- Legalett heating units are embedded in the floor along with the tubing, so they do not require a wall in the mechanical room to house boilers and manifolds. Units are accessed through a small hatchdoor flush with the concrete and can be placed anywhere in the home – in the mechanical room, under appliances, or in a closet.

- A metal box frame is hard-wired and embedded in the concrete to house heater units, the heater units themselves plug directly into the box to allow for easy removal for maintenance.

- Heater units use standard parts, so, long into the future when the warranty has expired, units can be easily removed and repaired by any electronics repair shop using commonly available parts.

- The first 10-12% of each zone output is fully-insulated, the second 10-12% is half-insulated – this forces the hottest air further down the tubes to more evenly distribute heat throughout the floor.

- With the system being entirely embedded in the floor, heat is also entirely contained in the floor, so there is no buildup of heat in the mechanical room as is common with hydronic systems.

- The reduced capacity air has to hold heat compared to water can reduce the risk of overheating.

- When installing a hydronic tube system you need to be very cautious, since accidentally piercing a tube will render the system ineffective. An air-heated tube system is not pressurized and there is no liquid to leak out, so an accidental screw put into an air tube is of no consequence.

- Each system and zone layout is custom-designed to deliver heat evenly. A detailed cut list and directions are provided, making installation simple and quick.

- Systems can be used in conjunction with thermal-solar air heaters, which are less risky (and less expensive) than thermal-solar hydronic heaters.

|

|

Insulating air tubes near the heater box output to better distribute heat © Ecohome

|

Can radiant floor heating provide all the necessary heat for a home?

In theory, yes, but it will not meet the requirements of the Canadian Building Code. According to code, ventilation air cannot be introduced into a building at a temperature below 17° Celsius at floor level, and not below 13° Celsius from vents located high on walls or the ceiling. Because of that, every fully ducted ventilation system in a home with any type of radiant heat will require supplementary heating to heat ventilation air back up to ambient temperatures.

Worthy of note: that requirement in code has nothing to do with whether or not a heating system has the ability to provide the entire heat load of a building, this is simply about comfort and making sure we don’t suffer any trauma from walking past a vent delivering air at a bone-chilling 16° Celsius.

With traditional heating systems like forced-air furnaces, ventilation air is typically mixed with the already-heated indoor air to achieve the temperatures listed above. Because that option isn’t available with radiant heating systems, a touch up heater must be used with ventilation air. Most HVAC systems will offer it and it is not an expensive upgrade.

Can air-heated radiant floors deliver enough heat?

Yes, they can. While it is true that much more heat can be transported by water than air, that doesn’t mean there isn’t enough. More power can be delivered by a Boeing jet engine than a 4-cylinder Toyota engine, but if you were purchasing a Toyota and you were given a choice between those two engines, which would you choose? Bigger isn’t always better. Any home-heating system needs to be designed and sized to meet the heat load of a specific building.

With an airtight and well-insulated bungalow equipped with an ERV or HRV using an inline fresh air make up heater (as required by code), a Legalett floor-warming system can provide all the additional heat a building requires under normal use. They have provided the entire heat load (excluding makeup heat) for buildings up to 35,000 square feet.

The floor heating system is only part of what the company offers, they provide engineered raft slab kits and have installed over 2 million square feet in North America.

|

|

2-inch air heated tubes © Legalett

|

Heating with electricity but avoiding peak rates:

An additional benefit that can be realized with any heated concrete floor (air, electric or hydronic), is that the floor itself acts as a thermal battery. A warmed slab of concrete will take a long time to cool, long enough to last through peak hours.

Floors can be kept on a timer, set perhaps to go on no sooner than 7:00 PM and off again by 7:00 AM, so you can avoid daytime peak rates. A well-insulated warm concrete floor can easily keep a house warm for 12 hours, allowing you to heat your home affordably with electricity in regions with high peak-electricity rates, without using fossil fuels.

Don Roscoe from Nova Scotia has build passive solar homes with warm air in concrete floors for many years. I "stole" his idea and I have built 3 houses part of his principals and the results were great. Never had problems with mold.

His idea: first layer insulation, on top vapor barrier, than gravel with air pipes and on the end register like a normal air furnace, on top the concrete slab floor. The air intake is from the top of the cathedral ceiling and blown constantly with a low speed fan to circulate under the concrete floor. The houses I have built were low cost houses. The only heat source beside having most of the windows on the south side of the house (passive solar) came from a small wood stove.(One house had a propane heat back up). The house performed not only great in the winter time with radiant heat it also helped to stay cooler in the summer time, by transferring some of the heat in the slab

Hello Richard. If it is possible, I would like to have your advice regarding a hot air floor heating sistem. Please contact me, or give me your contact. My email is [email protected].

Thanks!

Hi Richard, I'm looking at doing a new build with a similar setup with bringing warm air from the top of the house to hopfully heat the concrete slab in the basement. If you see this would you be able to contact me as well at [email protected] . I'd be interested to pick your brain a bit on this. Thanks!

Sounds like Don is quite an innovative builder, and you were smart enough to be inspired by him. It would seem you both avoided any ducts collapsing, that's good news, but if it were me I'd probably want to get the ducts cleaned occasionally to be sure anyway, particularly with a wood stove as there is usually more particulate in the air. Thanks for sharing Richard, we like innovative ways to distribute heat through a house to increase comfort and efficiency. Best regards.

I have invented a new way to create a wall cavity through which air circulates in closed-loop without ducts, tubes or pipes. Air pressurized from one side and vacuumed from another side. Cavity shape and design ensures maximum heat storage in the structure, uniform temperature distribution, reduces turbulence, and direct heat transfer between air and structure. Air is circulated by a unit equipped with dehumidifier; ozone sterilizer; and heater or cooling coil. This way any moist will be extracted from the wall, ozone will kill mold, the wall will be heated up or cooled down.

The cavity is 15mm and could be applied to the plastering or screed layer of the entire building surfaces (walls, floors, and ceilings) indoor and outdoor. It has a quick response time.

The invention granted an Austrian patent and filed it in the US. I am looking for a partner.

There is/ no reason that any building should depend upon only one energy source...and none truly do so.

But I've been seeing people say you can't build a 100% solar heated/cooled house since the early 1970's, and seen a great many buildings which had excessive cooling costs because they had too much solar intake.

I can see that this could have some advantages--one disadvantage is that an hydronic system can be built using less concrete. I'm not really sure how much of a problem stray screws or nails are in poured concrete flooring.

Any building hoping to have low energy costs should have an ERV/HRV in the design.

Hi Charles,

It does take a thicker concrete pad to do this, no doubt that is a drawback in cost as well as greenhouse gas emmisions. That said, with smaller houses it doesn't actually require that much more concrete since this design is a raft slab. Rather than having a 2 foot wide and 15-20" deep footing along the perimeter, this is a consistant 8" over the entire surface. So with a small total area, not having a footing offsets that thickness a bit when you calculate the total amount of concrete needed.

We will soon be building an air-heated slab like this for our next demonstration house, and at about 750 square feet, not having a deeper footing means that there is only an additional 2 cubic meters of concrete required than had we gone with a thinner slab that required a thickened-edge footing.

Slabs with larger total footprints would use more concrete of course, as the depth of the footing represents a much smaller percentage of the entire floor surface.

There are other benefits that come with a raft slab like this as well, the deeper concrete means more thermal mass to help balance temperatures. Thermal mass in a home can shave the peaks off of a heat wave in summer and perhaps eliminate the need for artificial cooling. And a raft slab is much more solid so it doesn't crack or shift.

Hi, just discovered you site - very exciting! Have you considered putting the tubes in a shallow sand bed beneath the slab, then you can use a standard 4" slab. I have a design (still to be built) using solar hot air panels for the air ducted under the slab - starting in fall to "charge" the sand bed. A compromise between a PAHS design and conventional radiant system.

Hi Noah ... intrigued by your post - and Mike Reynolds reply. I too - am designing a 'Thermal Battery' type of Air/Heat Storage in Limestone 'Dust' ( sand ) readily available here in Kentucky. I've investigated the "GreenHouse in the Snow" concept utilized by Russ Finch in Alliance, Nebraska. And - further research by "Green Cube Research", Oak Ridge, Tenn ... sounds like the 'Air-to-Sand' concept would work ... with enough MASS and proper air flow ? ... Your thoughts Mr Reynolds ? Thanks - to BOTH of you.

Hi William, I would first say that while I know how they work, I am not an expert in thermal batteries, nor do I know how much heat can be stored in limestone dust. But if you’re running tubes of heated water or air through any kind of mass, then it will store and later release heat. So it sounds to me like it will work, but to what degree I can’t really say. Using local materials is always a good idea when possible so that’s a plus, and if you feel so inclined please take some photos you can share with us and let it know how it works out!

A slab should have gravel and not sand below, especially in wet areas. With sand you could have some extra moisture do to capillarity.

Hi Noah,

Glad you like the site, thanks! About that design you mention - do you mean install insulation, then a layer of sand with ducts, then concrete? I assume you mean for the sand to replace some concrete and allow for the necessary depth to accomodate ducts, but no, given some of the failures in the past we did not consider that. Installing standard air ducts in floors has been done, sometimes successfully, but sometimes with complete failure as well so its not a risk we would take.

I do know of a builder than builds greenhouses that way, he uses the sand instead of concrete and runs pex tubes through it so it acts as thermal mass as well as the final floor. We do like when people share ideas so if I've mistaken something in the design let us know, and thanks for sharing!

You do want gravel under the concrete slab to prevent to much moisture do to capillarity.

What options do you have for flooring over a radiant slab like this? Concrete tends to be hard on the joints but you also don't want to use flooring that will keep the heat trapped in the slab. Any recommendations?

There are lots of flooring options you can put on top of a concrete slab floor, but just check with manufacturers first to make sure it can handle the heawt. What typically works are things like engineered hardwood, bamboo, or even a marmoleum floor. Here is out page on choosing flooring that may also help. What you shouldn't put down is solid wood, it will tend to crack and you may see cupping as well. Here is a video of an cork flooring installation, which we did in our last demo house.

In some cases, like the provider of this air heated floor, they do like to know ahead of time if you plan to include a floor covering so they can do accurate heat load calculations and ensure comfort. But, I’ll address your question from a general point of view in terms of heat delivery :

If you have sufficient insulation under the slab (like R20 and up) then a floor covering should have a limited impact on heat delivery. I wouldn't propose a wall to wall shag carpet with underpad, but you could lay down a 5/8th or 3/4 wood floor over top without great concern. Though be sure to check manufacturers recommendations to be sure a product you choose is suitable, and stick with engineered products rather than solid wood to prevent cracking or cupping due to heat.

It can also ad comfort to a polished concrete floor if you put runners in high traffic areas, rubber mats in areas where you stand like in front of the stove or sink, and small area rugs in front of a couch.

The reason I say adding a 5/8 wood covering isn't a big deal is because wood is about R1 per inch, so if you have R20 insulation or more below and about R.5 above, the heat is going the right direction so don't sweat it to much. It may slow the delivery a bit, but unless you add a lot of thermal resistance then any negative impact will be minimal, and worth the comfort of enjoying your home I would say.

Thank You - Mike Reynolds - for Sharing your experiences ... and Keeping me Up ALL night - reading and watching your Videos ! :] ... SERIOUSLY - your Unselfish 'sharing' means a LOT to those of us struggling to find answers to a BETTER way of living !

William that is really nice to hear, thanks! I'm really glad to hear you are finding value in the site and videos, and if you don't find all you need be sure to drop a question in the QandA section and we can try to help more. Best to you!

I am currently designing a home for acerage near Sydney NS, being mostly in the research stage. The current plan is to bury the first several feet of the home and earth berm the rest including a green roof. The layout, south to north, includes a tropical green house, an inground organic pool possibly combined with aquaponics, and finally the more standard rooms. While I will incorporate backup heating of some sort the goal is to have it totally solar-heated and cooled using solar chimneys, earth tubes and the like. I also plan on incorporating ventillation "to code" that I can control with the theory that the many greenhouse plants, once established, will be in a symbionic relationship with the mamals...they produce the O2 that we require while we produce the CO2 that they require, so exchanging inside air with outside air will be less necessary provided I monitor CO2 levels. The "greenhouse in the snow" plans incorporate a fan to circulate hot air from the top of the greenhouse into the ground below rather than venting all the heat outside. As my Solarium will be much larger I will have much more solar heated air available which I figured I could use for infloor heating, and a Google search to see if this has been done brought me to your excellent post. What I don't understand in your design is how your solar heated air enters the system. The only blowers are in the slab and given that hot air rises wouldn't the blower just be re-circulating the lower air without actually heating it while the solar warmed air stays up high, possibly reaching temperatures far exceeding the lower air? Would it not have been better to have the return air being forced to enter the solar heated pipes? Second question: is there any way to incorporate zone controls so that we are not still heating an already too warm kitchen (for example) while the garage/workshop remains much too cool to work in comfortably? In such a situation one would wish all the heating to be directed only to where it is needed. Third question: given that my design is for quite a large home I will be looking for ways to keep costs down, such as by using "mud" floors in many rooms. That would require standard footings but would be much cheaper than 8+ inches of concrete flooring throughout. Do you see any issues with that? Final question: As the flooring system needs to be closed loop, to prevent overheating in the summer what about having just the flooring a closed loop but incorporating an air to air heat exchange between that loop and the solar loop. With controls in the solar loop reading temperatures in the rooms to be heated (or not) it could decide which areas to send the heated air to including just venting it outside. As you should gather I find myself designing something unique and most likely untried in combination. I better at least be using sound theory for the component parts that have been proven to work, so any thoughts would be much appreciated.

There are a lot of points there and I don't entirely follow but I will do my best -

"What I don't understand in your design is how your solar heated air enters the system."

This is all a closed loop system. the Floor has its own fan to blow hot air. the ruturn air is fed to the panel to be heated, which has its own fan, and it is returned hot.

Would it not have been better to have the return air being forced to enter the solar heated pipes?

That's exactly what happens.

is there any way to incorporate zone controls so that we are not still heating an already too warm kitchen (for example) while the garage/workshop remains much too cool to work in comfortably?

Yes there are zones different zones. Not as many as with hydronic, but there are. And with a well insulated house and slab, the heat will move around, so it is less noticeable than forced air when you keep rooms at different temperatures.

given that my design is for quite a large home I will be looking for ways to keep costs down, such as by using "mud" floors in many rooms. That would require standard footings but would be much cheaper than 8+ inches of concrete flooring throughout. Do you see any issues with that?

The concrete is intergral to the structure in this case and can't be ommitted. That is not to say you couldn't do it, just not with this system.

Final question: As the flooring system needs to be closed loop, to prevent overheating in the summer what about having just the flooring a closed loop but incorporating an air to air heat exchange between that loop and the solar loop. With controls in the solar loop reading temperatures in the rooms to be heated (or not) it could decide which areas to send the heated air to including just venting it outside.

I don't understand the question, sorry. But I will explain what happens briefly - in the summer when floor heat is not required, the panels preheat domestic hot water. I don't follow all your points but I hope this helps in some way.

I'm curious about the cost and availability of the legallett system in my area (Western Oregon). It looks as though it might be a good fit. Expansive clay soils are very common here, and if a house is built to last, it will need to be able to withstand a massive earthquake.

I would like to learn more about the temp that is running through the tubing and how many cfm. Also, are there any other companies besides Legalett that deal with radiant air systems, I live in central Wisconsin, USA and have not found any similar products. Any help would be greatly appreciated.

Hi, I've just stumbled across this site and what a treasure trove of information it is! I'm hoping you can maybe help recommend a solution I just can't figure out for sure in my own.

We bought a house, built in the 60's, with ducts in the slab and a forced air system. It regularly fills with water when it rains and we have found ourselves frequently using a shop-vac to drain the water. During one particularly long and heavy spell of storms passing through, we drew out almost 180 gallons of water.

Six months ago we had the clunky old furnace removed and had a high efficiency unit installed in the attic with new ducts and ceiling vents. We'd really like to fill in the old, in-slab ducts and patch up the vent holes with drywall. What's the best way to fill in these ducts so we can be DONE with this health hazard?

I viewed the Legalet system demo at IBS a couple of years ago. I am curious how the resistance heating efficiency of the system compares to a heat pump system. In Texas where I live cooling is a much greater concern and insulated slabs are actually discouraged because ground contact is actually beneficial. Thoughts?

I like the arguments for heating with electricity, but why not use electric resistance heat? This system is easy to create zone heat for each room, and it seems like installing electric wires would be faster than the air pipes with all the cuts, sealing joints and extra insulation.

THANK YOUR for this info! Southern Minnesotan here. I'm planning a 1000 sq. Ft. single story ADU in my back yard (Double stud wall 12" dense cellulose, slab on grade), . A large white pine tree will shade the roof about 50% of the day, from noon or 1PM onward. Can a solar-air-radiant floor system work in our winters? (Heating Degree Days 4246 C. Cooling Degree days 440 C). What auxiliary heating in slab work (Electrical mesh or hydronic) would you recommend? Or other? THANKS again.

Interesting. I don't know the impact on concrete's structural strength or if the poly pipe expansion differences would cause premature cracking, but this might be useful for running geothermal heated 8ft deep, horizontal loop, corregated pipe (fan air only) to heat outdoor patios (I'd like to see it installed on driveway radiant systems).

Hi Kane

I don't know what sort of expansion there would even be with pvc piping, but if there was any, there is no way it would have the force to crack reinforced concrete.

The phase change of ice forming from water has that kind of force, but there is no phase change taking place with the plastic tubing. Their slabs are designed in such a way that they do not crack any where near the way standard slabs do, and they don't require (or allow) sawcuts.

About exteriors :

The air tubing is more than sufficient for heating the interior of homes, but heated air would not be able to deliver the amount of heat needed to melt the snow on a driveway, you'd need to do that with hydronic tubing.