Is EPS or XPS better for use in basement rim joists? Should faced or unfaced foam boards be used?

My home in south-central Pennsylavnia was built in 2001. The unfinished basement (walls and floor) surfaces are formed of poured concrete. One side of the basement has full-size regular casement windows, but the bottom of those windows is nearly at-grade. That wall is still full-height poured concrete. The rest of the basement is below-grade.

We aren't going to be drywalling our basement soon (maybe someday), but I want at least to ensure ASAP that the rim joints are henceforth insulated properly. I am considering installing foam board insulation with circumscribing spray foam in each rim joist (or maybe using purely spray foam to cover each rim joist). However, I can't tell whether XPS vs EPS would be "superior" for our basement walls and/or rim joists.

I'm way less concerned about R-values or project cost than I am about moisture (and bugs, to be embarassingly candid about the matter). I gather that I can always safely throw some fiberglass batting up in the rim joists to remediate any inadequacy of R-values acheived AFTER the use of spray foam (with or without foam board) to establish air seals. However, despite numeous apparently-professional sources (who don't manufacture XPS) recommending EPS over XPS for use in basement applications, I can't seem to shake the to-me-offputting observation that EPS is more moisture-permeable than XPS.

When insulating rim joists, isn't the supposed superiority of foam board insulation over mere fiberglass batting due to the observation that fiberglass is more moisture-permeable, and therefore more likely to support mold growth on the rim joists? Therefore, by extension, shouldn't one prefer to use XPS--for its lower permeability--versus EPS when insulating rim joists? Wouldn't that logic also translate to selecting a foam board insulation to cover the actual concrete walls of a basement like mine--at least when one considers that my basement concrete has already had many years to dry out (presumably about as much as it's ever going to dry out) following its initial pouring?

Lastly, if I'm going to go out and purchase EPS or XPS boards for installation in my basement rim joists, should I be looking for faced or unfaced foam boards to install there--and which surface of the boards (faced or unfaced) should be installed toward the outside?

Thanks!

Great that you are thinking this out carefully, but when it comes to the choice between XPS and EPS , yes there is a difference in permeability, but not as much as you may think. At 2 inches thick, EPS is about 1 US perm which is the the defining point of being a suitable ‘vapor barrier’ in residential constrution. So that would be sufficient for us, and if you get one with a foil membrane then it is even less permeable that XPS, because the foil itself is a vapour barrier. See this page all about rigid insulation panels -

The difference between Polyiso, EPS & XPS Foam Insulation & Styrofoam

We always choose (and recommend) EPS over XPS due to the fact that XPS has much higher greenhouse gas emissions than EPS. So if you are looking for suggestions we would say go for the EPS, and if you want added protection, source one with a foil backing.

RJ

Refering to the 2nd paragraph - I am being to told that the XPS proposed for the outisde of our 35,000 ft² 3-story multi family building has a GWP comparable to EPS. I am extremely dubious. Is anyone producing XPS blown with HFOs, and if so, what is the availability / cost?

Hi Eddy, you are right to be dubious. We have reason to believe that sometime in 2020 there will be a switch to HFO blowing agents with a much lower Global Warming Potential (GWP), but no manufacturers of XPS insulation have switched blowing agents yet. So as it stands, any XPS rigid insulation board you purchase will still have an impact several hundred times worse than EPS.

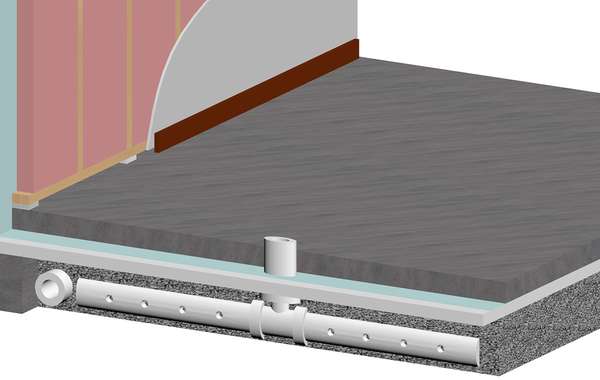

I agree with the reply, I've been doing a retrofit in a basement for over a year now. I started in a concrete crawlspace 4'8" high by 28 feet long by 12 feet wide with a concrete floor. The rim joists were stuffed loose like an afterthought, there black mold on those, no vapor barrier.

I caulked the ends of rim joist with silicone then added 3 inches of EPS foil faced both sides, and then added another 3 inches flush to edge of concrete wall.

On the initial blower door test there was a lot of air coming through the joists and 2nd test nil, fiberglass insulation was also AGAINST concrete wall R12 with a stud wall of 2 by 3 and it also had damp spots and mold, it was useless. I placed 3 inches against that as well using PL300 adhesive and secured it to the concrete with anchors (drilled every 4 feet in centre of 4 foot panel)

I may have to put 2 x 3 studs back and drywall for fire purposes, but I can't get straight answer from anybody on that...it's under 5 feet and so I'm told it's not required, while insurance companies argue it is a conditioned space and is required.

I'll be glad when I get to the 24 x 24 room attached, I plan on doing a continuous run with NO thermal breaks and also 5/8 on the floor before adding 1/2 inch rubber flooring and of course drywall.

Overall I'm impressed with product, I don't believe fibreglass or mineral wool belong in a basement unless certain conditions are met, and from what I've seen they never are, sorry, my 2 cents takes a lot of lines, hope this helps.

We always welcome 2 cents at any length Leo, thanks for sharing.

I think you may be in the U.S. so I can't speak much to building code requirements there, but in Canada any basement / crawlspace of 4 feet and over has to have insulation covered by drywall for fire purposes. Under 4 feet doesn't.

I would also agree with you that you should meet 'certain' conditions before putting fiberglass or Mineral wool insulation in a basement, proper steps should always be taken. Mineral wool worries me less than fiberglass since it isn't harmed by moisture, but I'd still be managing it properly anyway no matter the type of insulation I use.

I'm wondering though about the 'double foil faced EPS' if that's not actually Polyisocyanurate? That is not as resilient as EPS when met with exposure to moisture or water. There are a lot of rigid insulation panels, and foil faced rigid insulation boards make a great vapor barrier, it's just worth noting the characteristics of any particular product to make sure you're using it in the right application. Thanks for weighing in Leo.

Thanks Mike for heads up on ceiling height, and I am in Canada.

The insulation looks like foil but is a polymer. This from the company website in Canada "Quik-Therm multi-purpose insulation{MPI} is a continuous rigid foam insulation consisting of closed cell Type 1,Type 2 or Type3 expanded polystyrene {EPS} layered on two sides with durable and flexible polymer facers. MPI meets code compliancy as an air, vapour and/or radon barrier, when connections are foamed or taped. MPI is available in rolls or sheets. Optional T&G connections."