Basements don't have to be moldy, that is the first thing to realize.

It's easy to build a basement better, or to finish an existing basement correctly, we just need to realize that they behave differently than above grade walls and to build accordingly to effectively deal with the humidity found underground - and by doing so, stop the conditions that promote mold growth.

Depending on the age of your home, you may have some interior basement insulation or maybe none. You may have an exterior damp-proofing spray on foundation walls but likely not a proper drainage mat and perimeter drain or basement flood prevention measures.

Outside upgrades are the ideal correction given the way basement walls were left exposed in the past; however, unless you have serious structural problems or plan to excavate for other reasons, that can be an enormous extra cost for an interior renovation project. It is much more affordable to deal with most humidity issues inside the building. The basement insulation solutions proposed here are for those that have no exterior protection.

What causes mold to grow in basements?

Mold can grow on virtually any organic material as long as the moisture levels it likes and oxygen are present.

Because mold eats or digests what it is growing on, it can damage a building and its furnishings. If left unchecked, mold eventually can cause structural damage to building materials and can cause health problems - that's why we don't want mold in our basements!

Specifically we can prevent damage to buildings and building contents in the basement areas, save money and avoid these potential health problems by controlling moisture, where humidity in the air condenses, and by so eliminating mold growth.

Quick Fact Check: Eliminating all mold and mold spores indoors is virtually impossible, but controlling indoor moisture and the hidden moisture within basement wall assemblies will control the growth of indoor mold.

According to the EPA, indoor relative humidity (RH) in homes should be kept below 60 percent - ideally between 30 percent and 50 percent, In addition to preventing mold forming, maintaining the correct humidity levels may also have a bonus effect - discouraging pests such as cockroaches, silverfish (bristletails) and dust mites from populating the man-cave!

So, Step one, getting a humidity meter and tracking the relative humidity level in your basement is the first part of understanding the mold problem in any home or basement.

Compare budget options and special offers for manual humidity meters here![]() (we've tried and like the ThermoPro TP 50)

(we've tried and like the ThermoPro TP 50)

Or if you have a Smart home or are heading that way, See here to compare humidity meters online including smart trackers and alarms and find special offers and reviews![]()

Where the moisture is, and where it wants to go:

The key to building better mold free basements is to understand that there is a completely different set of challenges facing walls built below grade.

The greatest source of moisture to contend with above grade is the warm, humid air generated by cooking, washing and simply breathing. Below grade, it is that big porous sponge called concrete that is sucking up water from the wet ground.

A different problem demands a different solution - wearing a raincoat will keep you dry when standing in a cold rain, but it won't keep you dry when jogging under a hot sun. And unfortunately for many homeowners, the way basements were finished for the last few decades is about as logical as jogging in a raincoat.

Above grade, walls are designed to dry to the exterior. That is impossible below grade, but for some reason we still build as if it were. Despite the fact that interior vapour barriers in below grade wall assemblies are commonplace, frustrated building scientists insist that installing them is the worst thing you could possibly do down there.

Above is a photo of a basement being repaired after flooding. The mold damage you see is from longterm moisture exposure, not the one-time flooding event. This was a typical basement wall assembly, with a stud wall directly against the foundation followed by fiberglass insulation and a vapour barrier. Notice the difference between the studs against the foundation and the studs that formed an interior division wall; the vapour barrier did not protect the exterior wall from damage and mold growth. It caused the damage by prevented the wall from drying to the interior and instead sealed the moisture in.

As one of the foremost authorities on healthy basement construction, Professor John Straube of the University of Waterloo dubbed this typical type of wall assembly a "mold incubation chamber". For further convincing on the topic, read 'Built wrong from the start' by Joseph Lstiburek of the Building Science Corporation.

Better basement insulation techniques:

The materials and design you choose are very important to prevent mold and should be appropriate for the environment they are destined to inhabit. Be very careful how and where you install wood and fiberglass insulation in basements (If you must), and be sure they won't see prolonged exposure to moisture or contact with humid surfaces if you don't want them to go moldy.

Spray polyurethane foam (SPUF):

When SPUF works out, it can be one of the better performing products in basement applications. Being sprayed directly onto concrete walls, it ensures an even and total protection. SPUF has a high R value per inch, acts as an air barrier and a vapour barrier. However, it has been known to shrink after application, leaving air gaps and a lack of thermal protection.

Another downside to the original SPUF is that some blowing agents have a high global warming potential (GWP). For this reason, we like to explore less harmful alternatives whenever possible - though *January 2018 update: new blowing agents for spray foam virtually eliminate green house gases, read more here.

Probably the most worrisome problem (as reported by a SPUF installer) is that there is a great temptation for installation contractors to tinker with the chemical mix a bit, giving it more volume with less material, which is more profitable for the installers. There are not a lot of reported cases of this, but when it goes wrong it goes very wrong. Personally, I wouldn't let someone spray foam in my house without some pretty good references that I followed up.

All that said, here's how to proceed if you plan to insulate a basement with SPUF:

- Frame a 2x4 stud wall at 24" centres leaving a gap of at least one inch between studs and concrete.

- Shim up bottom plates to allow for water to pass under in cases of mild flooding.

- Have foam sprayed against the concrete wall. The space left between concrete and studs is crucial to allow a seamless blanket of insulation to create an air and vapour barrier. Unprotected wood touching concrete will wick moisture and eventually rot. One inch of SPUF will solve your problems; four or 5 inches will reduce heat loss and save you money in the long run.

- Have insulation blown onto rim joists if it isn't already done.

- Foam must be covered by drywall for fire protection.

- Don't install an additional vapour barrier behind drywall; latex paint will act in this capacity.

There have been a few nightmare cases reported where a SPUF installation went very wrong and apparently made homes uninhabitable. Given the fact that application involves a wet spray that hardens on surfaces, it is very difficult to remove.

These reported cases are rare, but if you are at all concerned, there are alternatives to spray foam for insulating basements listed below that work well in the battle against moldy basements.

EPS (Expanded Polystyrene), XPS (Extruded Polystyrene), Mineral wool:

SPUF is quite expensive; so rigid insulation panels and a 2x4 wall with batt insulation can be a much more affordable option - but you need to know the right techniques for a succesful and mold-free wall assembly for a basement application - read on!

Rigid insulation board against concrete adds R value, breaks the thermal bridge and raises the temperature of the stud wall, which helps prevent moist air from condensing. The stud wall allows for the installation of wiring, additional insulation and drywall.

Drywall should be attached directly to studs, latex paint will act as a vapour retarder slowing any outward moisture migration while also allowing walls to dry inwards.

You may hear that EPS is somewhat moisture permeable; this is true, but only slightly so and not enough to be a problem. According to Professor Straube, two inches of EPS has a perm rating in the range of 60-75 ng, or 1-1.25 US perms, which is right on the cusp of what is defined by building code as a suitable vapour barrier (60ng and under).

At that level of moisture permeability, an almost immeasurably small amount of moisture will be able to migrate into the wall, but with no interior vapour barrier it will pass through harmlessly. EPS, XPS and mineral wool are unharmed by moisture, and perhaps most importantly, EPS and XPS are unlikely to provide a breeding ground for mold. To see a showcase demonstrating the use of EPS direct onto a concrete basement wall see here.

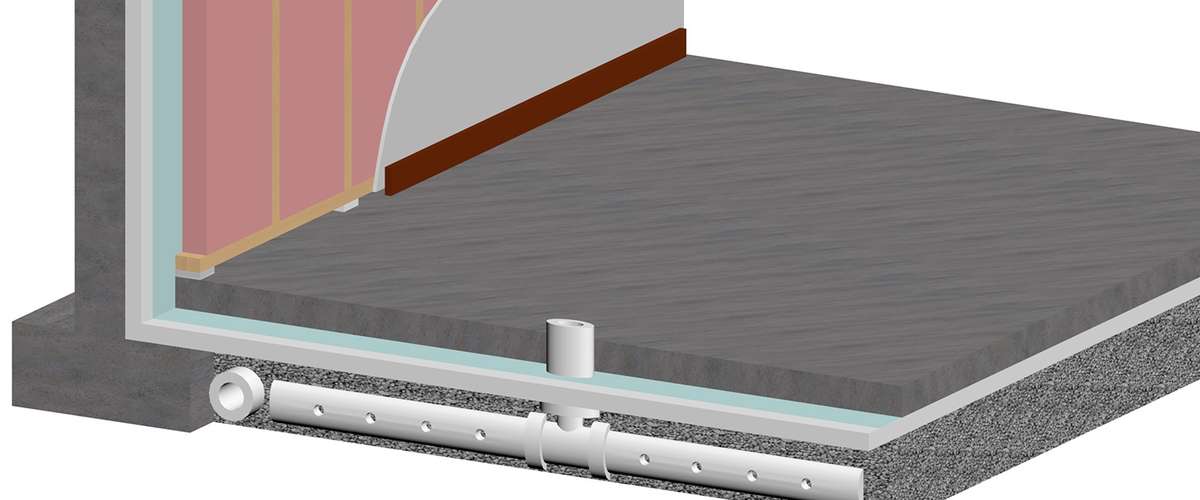

A polyethelene barrier can be included without causing harm (as seen below), as long as it is behind the stud wall, not in front. Specified correctly for basement Radon Mitigation, this will also act as a radon gas barrier to protect indoor air quality, and it will satisfy building inspectors who are not accustomed to seeing a wall without a vapour barrier and may not allow you to continue.

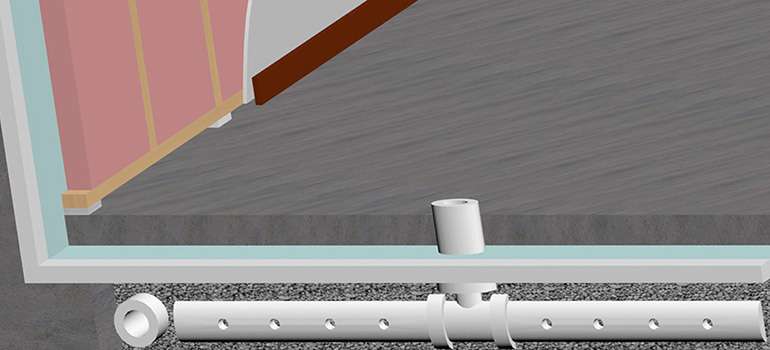

Note: the above diagram shows an ideal and complete basement renovation beginning with breaking and removing the existing concrete floor. Most older basements have very limited head room and owners are often reluctant to lower it even more by adding insulation to the floor. It also allows for the addition of a radon evacuation stack, which is the perforated tube and T-junction in this image.

By removing the concrete floor and maybe some of the dirt below it, you have room to insulate properly. Removing existing concrete is not as tough as it sounds - it can usually be smashed with a sledge hammer and removed in pieces. It does involve some hard work and heavy lifting, but the end result will not only be a more efficient and comfortable home, but a more valuable one at a time of resale and less likely to create the conditions that are best avoided - high humidity plus likely condensation points - both factors in producing a moldy, unhealthy basement.

The ideal Basement wall assembly to prevent mold growth:

- Install two inches of rigid insulation board directly against concrete. It is easiest to attach it to the wall with a couple of concrete nails or even some adhesive while you frame walls.

- Frame an interior 2x4 stud wall at 24 inch centres, pressed tightly against the foam panels.

- Install mineral wool batts in the cavities. Mineral wool is unharmed by moisture, and if it gets wet it will retain its shape and R value when it dries; fiberglass is not so resilient.

- Lastly, install drywall and paint it with a latex paint only.

This technique of rigid and batt insulation may require a few more steps, but it can offer you a greater R value per dollar invested than SPUF and it allows you to do a lot more (or all) of the work yourself.

For reasons beyond just performance, we prefer mineral wool or EPS over XPS. XPS has a slightly higher R value per inch, but like SPUF, the blowing agents are exponentially more harmful, about 200 times more than EPS.

What else helps prevent mold growing in basements? Ventilation!

Another considerable improvement in keeping basements mold-free is to ensure adequate ventilation. Whilst cracking open a window if your basement has them is fine if the humidity conditions outside are favorable, that's pretty hard to judge; so a better alternative is to choose a good quality discounted HRV or ERV system with an automatic electronic humidity control.

Along with removing contaminants from the air, there are health consequences from having either too much or too little moisture in our homes. There are bacteria, viruses, moulds and mites that will show up on either end of the spectrum if your air is either too humid or too dry.

As the EPA say, somewhere in the range of 35 to 50% relative humidity is generally assumed to be the best for avoiding most health risks and irritants. It’s high enough that you won’t have cracked furniture, chapped lips or constant nose bleeds, and it’s not too damp for comfort, condensation or heat consumption issues.

If you're in an older home sat above a basement, don’t panic. What we write in these pages is meant to inspire ideas and solutions, not fear and anxiety. If you feel good, your basement smells good and your windows (and walls) aren’t dripping, relax!

However, if your basement has a certain musty smell, or telltale black mildew and mold marks in corners or behind furniture, for peace of mind consider buying a hydrometer to measure your indoor relative humidity, which will cost you maybe $20 to $30 at most hardware stores. If you have an issue, and the humidity levels are off the scale, then chances are you've got a moldy basement even if you can't see it yet...

To be certain, get a humidity monitor and track humidity levels, see here

Top Tips: For a healthy, mold-free & comfortable basement:

- Test for Radon & install Mitigation if called for - because it's better to be safe than sorry

- Renovate using the best practices for mold free basements as oulined above

- Ventilate using a HRV or ERV, because let's face it - fresh air improves any Man Cave!

Further reading for basement mold prevention:

- How to choose between an ERV & HRV system for basement ventilation & Mold prevention - EcoHome Guide

- How much insulation does a basement need - EcoHome Guide

- 'How to build basements that don't stink' - Dr. John Staube, University of Waterloo

Vapou barrier is not for moisture but to keep the temperature from outside and inside balance or you will get condensation and mold. It a must have, they invented it for a reason. Think of it like double glazed windows. Have many basements have you damaged?

I think you have some of your wall components mixed up here, vapour barriers ARE intended to stop vapour, I've never heard that contested before. The title itself is fairly indicative of its intended purpose, it is intented to be a 'barrier' against 'vapour'.

I do commend you for not believing everything you read on the web, especially when something contradicts a practice that is ingrained in us, like putting poly on basement walls. So don't take it from me, keep on digging on the net until you are satisfied. I would recommend starting with Joe Lstiburek, the most recognized name in building science. Best regards.

Would like to confirm the information I've seen. I have a Toronto 107 year old semi detached home. Basement is 6' 4" to the joist and in 30 years have never had water in the basement. We do have efflorescence on the cement. Have long wanted to at least finish the walls to make it a bit more livable (maybe leave the ceiling joists as is) but have always been worried about mold. Am I correct to think that the EPS, 2 x 4, mineral wool batts, latex paint combination would be acceptable for my situation? Thanks for your help.

Without the vapour barrier, wouldn't the drywall get moist and have mold grow on it?

I get where you're going with that thought and its a good question, but no, the drywall should not be at any increased risk without a vapour barrier. For mold to form, or 'if' it were to form, that would likely mean there is a lot of moisture coming through from the wall assembly, and it was not being properly managed by ventilation equipment and dehumidifiers.

That moisture isn't going to escape to the exterior so you are best to let it escape to the interior where it can be managed, otherwise it will rot all the framing. If you have very high relative humidity you will be at risk of mold developing on anything and everything down there, drywall included.

I get that you wouldn’t want to put polyethylene between studs, and drywall, because the moist air from outside goes through the concrete and would get trapped within your stud wall. But why not polyethylene on the inside against the concrete?

I was just watching a video by Home Depot where they do just that!

Any thoughts?

Yeah, go for it. There really isn't a single 'best' way to design and build a basement wall, think of it as a physics problem to solve. You can stick a vapour barrier against the concrete, in fact when you put rigid insulation boards against it that is in effect what you are doing as foam panels will act to slow or virtually stop vapour. We have 'best practices for basement construction' page you may be interested in as it highlights different options.

Nice article. So how would you vapour proof and insulate the floor in this below-grade basement scenario? The obvious difference is it needs to weight bear. Would sheets of EPS covered with, say, plywood, then whatever your chosen floor surface is work?

Hi Jacob,

Yes, something along those lines would work. We would recommend you lay a sheet of poly down first then the EPS, that way you would be sure to stop the upward migration of moisture. EPS begins to qualify as vapour barrier at about 2 inches and it slows moisture even more the thicker it is, but as there will likely be gaps between the panels then you can't be guaranteed that the foam boards alone will stop vapour, but the poly for sure will.

If I am not finishing the basement in my older bungalow and I use this product:

Roxul

Comfortbatt R14 to insulate walls.

Should I paint the block wall with latex paint before insulating? Are you saying that I do not need a vapor barrier on top of the insulation?

Hi Mara,

I suspect that a block wall in an older bungalow would not have exterior moisture protection, so yes, I would add a barrier of some sort to the interior. As it is, the blocks are likely just continually absorbing moisture and depositing it into your walls. Latex paint would offer some resisitance to moisture, but for the effort and cost I would propose you just do it with poly, then the roxul. that way all the moisture stays on the exterior. Roxul isn't harmed by moisture, but there is no sense letting it in anyway as it just adds humidity to the home for no reason.

And on a slightly different topic, I would be cautious about how much insulation you add to the interior of a cinder block foundation. As it is only held together by mortar at the joints, it is nowhere near as strong as a concrete wall. For the life of the home, that block wall has likely not frozen in the abscence of insulation, so, by now adding insulation to the interior it will likely freeze in the winter, and that added stress could lead to cracking.

If possible it is best to insulate a block wall from the exterior, but we realize that isn't always affordable or even possible. But do check the condition of the wall, if there is any cracking already you may be best to consult an engineer before creating a new condition for the wall like letting it freeze.

But regarding that you don't want to finish your basement, what do you mean? only install studs & leave it like that? I can't imagine how you are going to apply that comfortbatt without a stud.

My concrete basement walls already have a 2x4 framed wall. The stud wall is not yet insulated or drywalled (it was this way when we purchased the home). We are looking to finish the basement this year. What would you suggest to do? We obviously wouldn't be able to add 2" rigid insulation directly against the concrete now.

My basement wall occasionally leaks so I'm having my walls waterproofed from the inside using the interior membrane and sump pump arrangement (membrane on wall, trough at floor with weeping tile leading to simp). I am not sure how to insulate over it because I don't want to leave an air gap against the wall above the membrane (it will end about 5' from floor). How to insulate over such a varied surface? SPUF might be the best solution but I seem to have run out of gold bars :)

I have this in my house and was looking at how to frame and insulate with this system in place. Can you tell me how you did it and how it turned out?

My understanding is that is in fact what you do to create a vapour barrier for the reason you suggest. The air on both sides of the vapour barrier on the inside of the wall is essentially the same temp so there is no condensation and the moist inside air cannot travel into the wall and condense against the cold concrete. But I'm no expert, it is just what a contractor told me.

I moved into the a house that had a room in the basement insulated with 4 inch polystyrene sheets and finished with a skim coat of what I believe to be outdoor stucco. My wife is reacting to whatever is on the walls. We know it's this room that is effecting her breathing because when I seal it off from the house her breathing improves. I have coated the walls with afm mexeseal but the off gasses are still bothering her. My next step is to rip out everything and start over. My question is can polystyrene cause breathing problems in a healthy person and if so is there another product that we can use as insulation that ticks all the boxes you have covered in this article? Also, can exterior stucco cause breathing problems if it's used inside?

P.S. I think the poly is exterior as well.

If the stud wall is done I'd at least go with the Roxul rather than fiberglass, and avoid the poly and go with the vapour retarder paint so it can dry a bit inwards. There is 'idea' construction and then there is what makes sense in an given situation. Even with the stud wall already you can still do it in a way where you are better off than most basements.

Hi Adrian

I was recently speaking with a doctor that specializes in environmental health issues, and she says that a lot of people are negatively affected by foam insulation. I am not an expert in what materials will cause people grief, and it would be different depending on the person, but myself I don't see a big connection between exterior stucco and interior air quality. That said - we had a woman who is extremely sensitive to chemicals come and visit our Edelweiss House and she was fine with it. She did a smell test with individual materials, perhaps that could be a valuable technique for your wife before installing. I'd say you'd be best with Natural materials like Roxul which is a recycled stone dust. It really depends on her level of sensitivity. Here is a link to the demo house, all the products there passed this one woman's test, no guarantee they will work for your wife but its a starting place at least. Good luck! http://www.ecohome.net/demo...

I'd need a better visualization on that Dan if you can drop a drawing or email me at [email protected]. SPUF works great in such capacities, granted it can be costly but maybe limit its use to where its absolutely necessary? Also - new blowing agents for spray foam make it finally a green option, and non-toxic as well in case that helps with your decision - http://www.ecohome.net/news...

Sorry for the painfully late reply Jason, but at this point I'm trying to do some catch up in case others have similar issues. If you keep the basement relative humidity low enough (under 50) you shouldn't have a problem, there is a bigger concern with moisture moving inwards than moisture moving outwards, that's the reason for the slightly more permeable 'vapour barrier' would would more accurately be called a 'vapour retarder'. Moisture can build up inside the wall assembly and cause mold behind the drywall if you have an impermeable vapour barrier there.

Thanks for your help Mike. I've removed the styrofoam insulation from the basement and will frame it, Insulate with Roxul drywall and no VOC paint as the vapour barrier. The walls were completely dry when we removed the foam. My question is should I leave a 1"air space between walls and Insulation or can the ruxol be against the wall.

5 years later but wondering what you ended up doing and if you've had any problems? I have studs up and wondering if I should use rockwool between studs and leave the 1 inch air space. If I pushed the rockwool against the concrete there would still be a gap behind each stud. Thanks for any info

That's great news that the walls were dry. Since Roxul is hydrophobic it won't absorb any moisture, so according to our engineer its fine up against the wall, the studs can hold it in place. We got our vapour retarder primer from Benjamin Moore but it was not zero voc, only 'low' voc, I'm really not sure what other manufacturers offer. Another option as well is a breathable 'vapour barrier' called Membrain from Certainteed, the pores open up and let moisture pass when it gets too humid. A lot of times building inspectors will call you out on not having a 6 mil poly vapour barrier, this is a way to keep them happy but not rot your walls. I feel bad for not getting back to you sooner, drop me a line if you like and maybe we can chat, your wife's reaction to air quality ups the stakes a bit so I want to make sure to steer you right. [email protected]

Mike,

Great article - it is very helpful and providing much needed guidance.

Question: The basement of my 45 year old house has a 2x2 stud wall (sitting on concrete slab, not on EPS spacers) packed with fiberglass insulation, all directly against the block wall, faced with wood paneling. There is no vapor barrier and there does not appear to be any mold, and I don't have any leaking problems. In winter the room is a bit cool, but I attribute that to the carpet on slab with no other insulation. We are in Southern Ontario, so winters are generally cold.

I am redoing the space and am wondering if I should take the walls down and replace with EPS/mineral wool/drywall as per the article; or just put the drywall up on the existing 2x2 studs? I am already planning to install an insulated sub-floor.

What do you think?

Thanks in advance!

Great article. What do you recommend to use below flooring to provide a vapor and insulation layer? I'm looking to lay carpet down on the slab without radiant heat below it and am concerned about both moisture and the low ambient floor temperature.

Hi !

I am interested in going with the solid XPS panels solution for my basement walls as it will be pretty cheap to finish (around 2400$ CAD including drywall and paint) and I can do it myself. However, I was wondering if this technique can still be used if a waterproof membrane was installed on the exterior of the foundation wall.

Amdry insulated subfloor panel

Finally someone with common sense. Poly is the worst and I'll go as far as saying Tyvec is a hoax also.

If the concrete is acting like a sponge and we place rigid foam against it , is there not a chance for a mold to grow between the two?

Thanks

I am having a new home built with 9' poured walls. I am going to finish the basement myself. My concern is insulating the floor. I don't want to use treated wood as batten due to I know how it curls when drying. It would take a lot of screws to keep flat. Is there anthing wrong with what I propose? Lay a plastic vapor barrier down. Put 2" foam boards down. Put 23/32 plywood down. And then another layer of 23/3 plywood down on top perpendicular. Screw both sheets together and have carpet installed on top? Is it ok? Is it overkill? Does the plywood need to be moisure resistant? Thanks

If you have a layer of poly and then 2 inches of EPS foam, I wouldn't be too concerned about the plywood as I think you have separated it well from any chance of moisture assuming the following : If it's a new basement you are building, then presumably you have the opportunity to take some additional steps towards protecting it, meaning - proper exterior water protection, drainage, a weeping tile that can drain bulk water away from the foundation, and a sump pump.

But I do wonder if you won't find it a bit spongy if you have a plywood subfloor laying directly on a couple of inches of foam. If you take the steps to protect it from flooding in the first place, I might also consider the idea of laying down a water proof dimple membrane with a bit of space for any incidental water to move, then some 2x3s with insulation boards between them, then your plywood subfloor.

I recently framed my basement walls with 2" of eps foam fastened to the exterior wall with all seams taped and corners spray foamed.

I left a 1" gap between the foam and framing and when I insulated the walls with r12 batt insulation I noticed moisture forming behind the insualtion where the insulation was contacting the foam. What would be causing this? And what should the next course of action be to correct this??

Does anyone have any information that would help? It would be much appreciated.

Hi Kurt

I'll recap that to be sure I have the assembly correct -

2 inches of EPS foam attached directly to the concrete with no air gap between the foam and concrete joints taped, but a 1 inch air gap between the interior surface or the foam board and the stud wall, and fiberglass batt insulation in the stud bays. Correct that if any of it is wrong, and, do you have a 6-mil poly barrier sealing the whole wall together?

You have a source of moisture somewhere and it's a case of finding it, but also a matter of letting it out. Poly vapor barriers on the interior surface of a basement wall are not at all a good idea, it will trap the moisture. So if you have one, that's at least part of what is causing the problem. Better is if moisture in a wall can dry to the interior (since it can't dry to the exterior), and then it can be handled by ventilation equipment or dehumidifiers.

Without a poly barrier the moisture shoud be able to dry to the interior, unless there is something else really wrong going on here.

That is correct about the wall assembly, but I have no poly on the walls.

I noticed moisture was forming where batts were contacting the foam. I'm thinking this is due to the warm batt touching the cool styrofoam and creating condensation. I've have a dehumidifier running and it's at about 38%. I've also just had an HRV installed but don't want to hook it up until the basement is taped. Will and HRV correct this or am I overthinking it? I would just hate to finish the basement and have issues when this would be the time to solve them and correct it.

Thanks for your reply Mike!

Is the concrete floor in the wall and 1 inch gap area insulated or exposed to the gap? If exposed, is it possible that is your moisture source? Or possibly from other parts of the basement if your wall wasn't fully sealed up yet?

I spray foamed the bottom of the foam panels so there is an insignificant amount, if and concrete showing. The bottom 4' of the insulation doesn't seem to sweat. Just the part of the foundation close to and above grade.

Hi Mike, can you elaborate on the floor insulation approaches? I thought most poured floors have some sort of membrane/vapor barrier underneath the pour. Wouldn't adding another vapor barrier above the floor be a problem in that scenario?

Hi Eric,

If there is a vapor barrier already, then presumably the concrete would be dry as it is protected from below and able to try into the air above. Adding another vapor barrier wouldn’t be a problem for that reason, but also because there is nothing in a floor that can rot. If you aren’t sure if there is a vapor barrier then you really should have one, and most recently built basements would have at least 1.25 inches of EPS insulation then a vapour barrier, so really all that would be sandwiched between vapor control layers would be concrete.

And, the assembly shown in that image includes a 6 mil poly barrier for radon gas protection, but worth noting is that 2 inches is about the thickness when EPS rigid insulation acts as a vapor barrier anyway.

And, good on ya for catching and questioning that ‘double vapor barrier’!

I have an older(1944) built home that we just bought about a year ago. I recently built a 5th bedroom in the basement, and discovered that behind the wallboard, there was no insulation at all, just bare concrete. I think I followed your advise and glued 2 inch ridgid board directly to the concrete, spray foamed the top gaps between foam amd joists and rim board and tuck taped all seams.

I then layed down some barricade subfloor panels thoughout the room, then built a 2x4 wall snug up against the ridgid board on top of the subfloor, and insulated these cavities with roxul insulation. I then drywalled over that and primed and painted with latex paint. My question is, would that be a correct way of doing this? Also I am now about to start the rest of the basement, should I continue this way? Or would I be far better off just to get a spray foam guy in to spray directly on the concrete? And the flooring in the rest of the basement is also a concern. A had debated laying down some dimpled membrane with plywood as the barricade flooring is a bit if a pain to install in a floor that wasn't poured very well. Any suggestions?

What you did on the walls sounds about right, so if you're happy with the price and work load I wouldn't necessarily switch to spray foam unless you're sick of doing the work because it will likely cost you more. If you do go with spray foam, see our page here to choose the best brand -

New HFO blowing agents for spray foam will make it over 1,000 times less harmful to the climate

The only thing that concerns me is the barricade floor. I am no suggesting you lift what you did, but I may add a step - a layer of 6 mil poly ahead of time. since those panels butt up against each other with the vapor control layer at the bottom, there is no way to seal them. If you don't have a vapour barrier below the slab (which was not a practice done in 1944) then the concrete will constantly be wicking moisture from the groudn below. So moisture could migrate through the seams between each of those panels and cause the OSB to deteriorate over time. Again, I'm not suggesting you lift your existing floor, but this would be a little upgrade that may extend the life, and it means you aren't switching building materials and causing a change in floor level.

One more question. I keep seeing conflicting information about EPS vs XPS ridged foam. If I stick with the method above(no vapour varier, and insulating the wall after the foam is glued to the concrete wall), what is your recommendation, can I get away with EPS?

Hi, thanks for this awesome article. I just wanted to make sure I understand what you are recommending correctly. If I use mineral wool rigid board insulation (e.g. Comfortboard) instead of XPS or EPS panels right against the concrete, would it be appropriate to put in vapour barrier polyethylene on the interior side of the Comfortboard (stapled to the exterior of the stud wall), and then fill in the stud wall with mineral wool bats and finish with drywall? I ask this because it seems to me that mineral wool is completely permeable to moisture (unlike the foam products), so it would seem important to compensate for that by adding in a vapour barrier. I live in Edmonton, Canada, so our winters are cold.

Hi Mike, thanks for the great article. I have the same question as Luke and did not see a direct reply RE: putting 6mm poly vapor barrier against back of wood stud wall (i.e., between concrete wall and mineral wool batt)

for my case, I live in Ottawa, house built in 1990, poured concrete foundation below grade. Did have a few cracks in foundation with water seepage during previous ownership but we excavated the affected exterior foundation walls and applied a membrane.

Inside the concrete wall, stud frame already in place so I was thinking to line 6mm poly behind stud frame to create an air gap between studs and concrete wall (nothing in between) then line with rockwool sound n safe batts between studs, then drywall. Does that sound right?

Hi Mike, my home has framing on the exterior walls of the basement. I am about to start finishing the basement and I noticed there is no polyethylene between the bottom plates and the concrete. The bottom plate is also regular SPF. Not pressure treated. What should I do? Do I need to rip out the walls and start over?

Hi Frank. Tough call, it's best to keep a moisture barrier between them but I imagine that will be a lot of work. Is there any signs of water damage on the floor from previous flooding? Is it humid? Most basement finishing is done exactly like that so I'm reluctant to say "yeah rip them out". So I assume there is no vapor barrier against the concrete behind the stud wall either? That's where it's best to have it. If you leave it as is just be sure not to put a vapor barrier after the studs to seal it in with the wet concrete, as you likely read above, that's the biggest and most common mistake ever made in basements. If there was anyway to pry the wall up a bit and slip some plastic under it that wouldn't be a bad addition, but really I'd base it on the humidity level and chance of flooding. And is it a new house with a vapor barrier under the slab?

Hi Mike, thank you for your quick reply. The house was built in 2005. No idea if there is a vapor barrier under the slab but I will try to find out. There is no sign of humidity or water damage in the basement. Also no chance of flooding as we are on a hill. I will check if there is a vapor barrier behind the wall against the concrete. Who knows, maybe I will be lucky!

I'm adding a 2 piece washroom in a finished basement. The entire basement was finished with tar paper on foundation wall 2 by 2 framing with fiberglass insulation, vapour barrier and drywall. I have gutted the room down to foundation wall and am planning to use 2" rigid glued to wall 2 by 4 framing with roxul and drywall. Is this best approach given that the rest of the basement was done incorrectly according to this article?

Can anyone tell me if the manufacturer ISOLOFOAM is giving me the right advice for the installation procedures for their EPS High Density (16 PSI), 2 1/2" thick?

My 6" thick basement slab is not insulated at all, only 7" of gravel underneath, straight onto sandy soil.

A possible issue I may have though is that if my basement floor ever get flooded again (got exactly 2" of water onto it 2 years ago due to the 5' street ditch being jammed with ice and snow), the entire insulation and subfloor may end up floating on water.

I was thinking of leveling the existing rough concrete floor to level it so as to not have air gaps below the foam boards. So, to smear the sand & cement mix on the floor, thereafter place the HD EPS boards right onto the new uncured concrete layer to seal and hold the foam boards into place. If needs be, place the poly over the 2 1/2" EPS boards for some radon protection? Would that work?

If you've had flooding before I'd install a sump pump before insulating your basement floor. levelling is not a bad idea if you have the head room you can spare, maybe use something like a 3/8th crushed stone though and leave it as is. I don't see why you'd need to pour concrete, if you cut the EPS to fit fairly well and even spray foam them at the walls then they wouldn't need to be set in concrete not to move. If it's just stone instead of concrete you can better ensure the EPS won't get saturated with water as it will have better drainage to your sump pump. And it's really easy to level using a transit, which you can rent if you don't have one (not many people have one).

And yes you can put your poly / radon barrier on top of the EPS. Here is our page on how to mitigate radon gas in basements, that will help you do that properly if you're doing it yourself. You need to be sure to have a passive or active radon stack and vent it out of the house, out the rim joists is a great place, that way you can see it easily. Sometimes they get frost build up and you can clear it. If its on your roof you'll never know if it's blocked.

Thank you, Mike for this article. My husband and I would like to finish 3/4 of our 1000 sq ft cinderblock 1959 basement in Raleigh, NC. We get a few hearty freezes a year. We do not have water in the basement, nor french drains i'm guessing. We do have efloerescence in one corner but we hope we've fixed this with gutter repair, not 100% sure though. Years ago we also halfheartedly painted the walls with limeprime. I was thinking of just staining and sealing the concrete. I am mold sensitive and mildly chem as well. As long as we keep the dehumidifier going i'm currently just fine but without it I am not. It's not musty at all with it and only very mildly without.

My questions are:

1. can we finish the ceiling with dry wall? 2. We have large galvanized steel hvac ducts running below floor joists. Can we hide these in dry wall too and do we need to insulate to prevent mold? Is it risky to finish the ceiling? 3. My husband already installed interior wall steel studs and mold resistant drywall, just in case. What is the best move for exterior walls? Can you advise what would be most ideal for finishing the walls? We are willing to pay to do it right but the sky is not the limit on what we can spend. But lots of sweat equity on hand. We want to be eco-friendly. 4. If we divide the finished space into 3 rooms plus bath, would each space require a dehumidifier or would leaving the doors open so they are all connect suffice. 5. Finally, do we need to treat the air? (i.e. hvac) to keep it dry and healthy or is our dehumidifier enough? Our radon level hovers around 1. Thank you so much, Mike, for what you do and for sharing your expertise. warm thanks, Aminah

I have seen people using house wrap against the wall before building the stud walls and installing insulation. There point theybsaid was to prevent the water yet let it breathe. Does this make sense?

Hey, I am redoing my basement soon and had a couple questions. I live near Chicago, which if I looked correctly puts me in climate zone 5. The house was built in the 60s so I doubt theres exterior barrier. I have a cinder block wall basement that currently has wood paneling covering it. There appears to be some water damage from when the house was empty do to forclosure, but we havent opened the panels yet to investigate further, so obviously I'll know more on condition after. I was thinking about putting some vapour barrier paint on the block walls then follow it up with possibly with some 2" EPS glued to the wall with a stud wall built after with drywall. I was just curious on possible recomendations based on the info given.

Hi Mike,

In September 2021, we had waterproofed our foundation (Rub R Wall), and a simple board wrap around the water proofing spray. French drain and sump pump installed as well.

We are now looking to redo the insulation in our basement (i.e. ~4-5 feet below grade) And wondering if you would have a recommendation between spray foam VS Rockwool. Is there also a recommended period for the interior basement walls to dry first ?

I have a home 3 years old. Basement is not finished and looking to finish. Concrete walls and has plastic shiny bag insulation on walls tacked to the concrete. Aprrox 1/2 of the basement is below grade and other half we have a walk out. Does the shiny bag insulation need to come down prior to me moving forward finsihing basement or could I go over the existing bag insulation with rigid board insulation and drywall? I'm in Zone 5 of the US

Hi Chris, I'm not sure what you mean by 'shiny bag' insulation, is it foil? The most important thing with finishing a basement or insulating walls is to not trap moisture inside, and certainly not with wood framing. Moisture needs to be kept out of the basement by stoping it at the source, which is the concrete. Describe that better if you can please and maybe we can point you in the right direction. Let us know the composition from concrete inwards - if there are wood studs, rigid foam, fiberglass, vapor barrier, let us know the order.

I love how the MOST important factor regarding mitigating mold growth is proper ventilation and yet there is very little discussion in these comments about the condition of basement spaces. Do you have forced air in the basement? Supply and returns? A dehumidifier? Fun fact; humid environments will not grow mold if properly ventilated. And yet so many people are quick the suffocate their wall systems with plastics and foam. It was put best in the article when acknowledging that above grade walls need to be ventilated to the exterior... Well, surprise... Below grade walls need to be ventilated to the interior. They just do. It's really unfortunate that some codes enforce vapor barriers on interior basement walls. We all know how building science "facts" tend to change as new studies come out. And as for the toxic foam attempting to hermetically seal every nook and cranny - Consider this as cakey makeup clogging the pores in your skin. Not Good. In most cases, you do not even need to insulate the interior side of the basement wall if completely below grade and properly conditioned (heated and cooled). Earth is an amazing insulator which is why so many animal species build burrows and dens to combat the winter months. The rim joist is the only area that truly needs to be insulated with a nice natural non-toxic wool insulation. This space should be boxed out with a soffit around the perimeter and ventilated to the interior with pass-through grilles. Think more like nature.

Hi Stephen

Earth is not an insulator in any modern sense of the word. The little critters that use the ground to stay warm are the ones that weren't able to find a nice batt of fiberglass insulation in a wall or crawlspace they could burrow into, the ones that did are much warmer and happier. If you don't insulate your basement in a cold climate you are needlessly paying to heat the ground, full stop. And it will keep taking as much heat as you throw at it.

Here is a page about how much insulation a basement needs, which describes how heat moves and includes a thermal image of the difference between an insulated basement floor and an unisulated one.

I like your comment to 'think like nature', which I agree with, but that means respecting the laws of physics. Nature doing its thing means heat moving from where it's warm to where it's cold, and in a cold climate that means moving from your warm basement to the cold ground if you don't take steps to keep the heat inside your building envelope with insulation.

We had water come into our lower living area that is partially below grade. Ripped out carpet and half wall and fireplace. Had a company do interior footer drains and a sump. I cleaned the block wall and sealed any small cracks I found. Painted black with oil based Zinsser sealer paint. Used spray foam to seal any air leaks I could find. Put up R 7.5 rigid foam board and taped seams.

my question: I can only use 2x2 ferring strips for the wall without creating a ton of extra finishing carpentry work for myself with the ledge trim etc... so that's what I plan to do. Is there a rocwul product that is best for the cavities? That's what I was planning to use but wasn't sure if I can compress it.

I think you would be best to try Rockwool comfortboard rather than batts (Rockwool used to be known as Roxul), They come in various thicknesses starting at one inch. If you can't find it, you could safely continue with rigid EPS foam boards. Mineral wool batts can be compressed without affecting performance but they are a lot more dense than fiberglass, so trying to squeeze a 3.5 inch Rockwool batt into a 2 inch space would quite a challenge!

Hi Mike,

Just want to confirm something. I planned on gluing 2" foil faced polyiso to my basement walls, leaving a 1" gap and then installing my studs. Should I not be using the foil faced?

Hi Jeff,

Polyiso isn't the greatest for humid areas as it doen't do well with moisture. I'd stick with EPS, and if you're looking to the foil as a way to prevent moisture infiltration you can find EPS with foil as well, and yes, its a good thing if you're only putting 1 inch. No need to leave the gap, you can stick the stud wall right against the foam, insulate the stud bays, and put drywall right on the studs, and remember - don't put a vapor barrier behind the drywall!

Thanks for this informative article. We are looking to reduce heat loss in our unfinished basement (1920s house) and considering having HFO sprayed directly onto the thick concrete basement walls. I am concerned about some of the cons of using spray foam. I was considering rockwool comfortboard (attached directly to the concrete walls) as an alternative, but not sure whether this could lead to moisture problems with moisture leaking through the concrete walls and being retained by the comfortboard. We can get moisture in the spring and summer when humidity is high and run a dehumidifier during this time. We are not planning to frame the walls at all, so didn't want to combine with framing and batts. Would this be a viable alternative to using spray foam in this sitution? Are there any others? Thanks for any advice you can provide.

Hi Karla, using mineral wool in basements is always a wise choice because of their ability to withstand humid conditions. An easy way to improve that plan would be to put a poly vapour barrier against the foundation wall, that will prevent any moisture in the concrete from migrating through the walls. Vapor barriers on basement walls are a problem because historically they have always been placed where they do no good but lots of harm by trapping moisture in the walls with wood and insulation. When placed against the concrete they will actually keep the wall dry.

Hi Mike! I need to remediate a moldy basement of a home I will be moving into. The company said it still needed to send me an estimate for repairs, foam installation and vapor barrier. That led me here, so cool the q&a have been ongoing for years! However, now I'm just confused. The house was built in 60s. There is a small crawl space, sheet rock and non weight bearing studs that need to be removed. I live in the northeast, very close to ocean. I already have health issues from exposure to mold toxicity 2 years ago. What are the basic materials that I need to consider for the basement to try to prevent mold? What's difference between vapor barrier and an alternate barrier type paint? There is a sub pump, a basement dehumidifier is like having a floor here. How do you ventilate a basement without a pests invasion?

Do you have suggestions for replacement materials? thank you for article and all your time-britten

Hi Mike,

Several years ago I applied Radon Seal/Ion Seal to the basement walls and floor. The manufacturer claim the sealant soaks 2.5 to 4 inches into the concrete. It is a lifetime seal. We have put this to the test when we had leaking from our HVAC. Could this be considered a good vapor barrier prior to following your steps?

would there be any to harm condion this space by painting the walls and floor, not insulating? We would have continuous ventilation down there.