Are foam insulation panels a green choice?

The short story is, maybe. And the long story is, well....

When we launched Ecohome about a decade ago, our mission was to create a green building website where homeowners and builders could learn how to make informed design and product choices and build sustainable, energy-efficient homes. A place where a dialogue about the true impacts of building products and practices could be had, where the pros and cons of different materials and ways to build were openly debated. It is very easy to jump to conclusions either in favor or against certain products based on outward appearances.

Foam insulation in all its incarnations (and there are many) is one of those product categories that really rubs some people the wrong way due to the nature of the raw materials and the manufacturing process. But its reputation may not be entirely deserved anymore due to changes in some products, and the reality of natural resource management across the globe. So we wanted to revisit it.

What makes a building product green?

We are often asked ‘what is the greenest home you can build’ or ‘what is the best home insulation’, and honestly, there is rarely one single right answer.

In that spirit, I wanted to take a closer look at EPS foam insulation or ‘Styrofoam insulation’ as it is often mistakenly called, which it isn’t. It may seem like splitting hairs, but Styrofoam is a brand name of XPS insulation, it is not EPS insulation, and environmentally speaking they're very different - read more here.

A good part of the reason why EPS foam insulation gets such a bad rap is because it is so often confused with the more harmful foam products on the market, when in reality it isn’t actually as bad as people think. They are easily distinguishable from each other, see below:

The criteria for what ‘eco-friendly’ or ‘green’ building products are can vary by person, and it will depend on what your individual priorities are.That may be sustainability, resiliency, indoor air quality, pest resistance, etc. And even those ‘eco’ terms I just mentioned by the way, can start a discussion on their own. We know they get used to death, and they have somewhat lost their meaning because of it. But if someone searches ‘what is the most eco-friendly insulation?’ - Well, we want them to find the right information, so we have to use it.

Due to the massive success that one can have by luring readers in with those search terms, there is now an abundance of home décor websites that find internet rumors they can repackage as ‘sustainable building guidance’, which is how people can get talked into silly things like using plants as air filters or buying magic insulating paint. You won't find us feeding you fluffy pseudo science here.

As a global community, all we can do to protect ourselves from runaway climate change is to weigh all the variables and make the most informed decisions possible while we balance quality of life with reducing our personal carbon footprint.

And, short of parking yourself on top of a compost pile and waiting to meet your maker, there is simply nothing you can do on this planet that will not, in some way, lead to environmental degradation. Every step you take wears out your shoes and every ‘save the whales’ sign you make uses cardboard and wears out crayons. So, with no further adieu, foam haters – let’s discuss. And for the record, I believe saving whales is worth sacrificing a few crayons.

Is foam insulation eco-friendly?

I didn't think so, then I started to, then I changed my mind, now I sort of do again. And that's as a guy that lives in a house insulated with foam. And I’m still open, so by all means please make your case for or against foam insulation in the comment section below and try to change my mind.

When I started to design my own house back in 2002, I bounced between various wall assemblies, but not based on any hard facts. I listened to the advice of those that had strong opinions, but that weren't always born of diligent research as much as reputation. I realize I’m going off on a tangent here but I promise I’ll land this plane soon, and it will metaphorically land on foam so please stick with me.

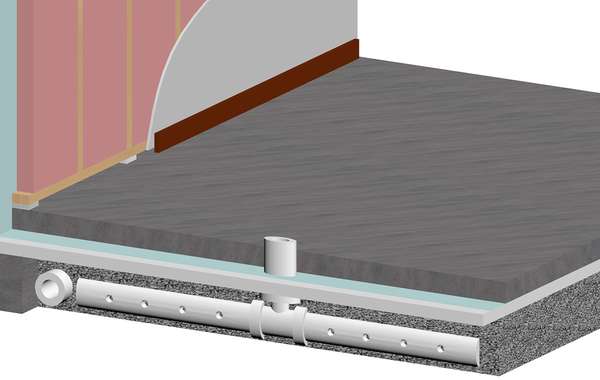

I trusted the opinions of my mentor builders more than I trusted my own opinions in some cases, whether they actually knew better than me or not. Sometimes they did and sometimes they didn’t. What I ended up building was a timber frame house with SIPS walls (structural insulated panels), that have an EPS foam insulation core as insulation.

So, which home insulation is best?

I originally wanted to build with straw, but I was led to believe that in pretty short order it would be a moldy walls full of insects. As it turns out, that’s not necessarily true. I considered Hempcrete, but it seemed very labor-intensive and expensive, it also wasn't a super-performer or airtight. That's still still sort of true, though hemp is one of the more promising up and coming bio-based building materials.

I was steered away from cellulose since I was told it settled, which was and wasn’t true – loose-blown settles but dense-packed cellulose insulation doesn’t settle. We didn’t have mobile devices back then where we could read the news, so the world was awash in newsprint that ended up in hamster cages, wood stoves and landfills. So in hindsight, cellulose would have been a great choice as there was tons of it around, and currently there still seems to be.

In the end, for performance and cost, for good or bad, I was talked into insulating my home with EPS foam SIPs. I was a hard sell at first, but for reasons of cost, simplicity and reducing my building anxiety, I succumbed. I was told that it was ‘steam blown’, which is a partial truth (it's mostly steam but also includes pentane gas), but still it eased my conscience back then.

At the time, I really thought I nailed it – airtight, compact, well-insulated, triple-pane windows, passive heating, and SIPs walls. Would I build it the same now? Nope. Do I hate it? Nope. It is what it is. It’s not as great as I first thought, but it works fine. There are some things that I didn’t anticipate and some things I don’t love, but hey – hindsight is always 20/20.

So…how could a true-to-the-core green builder like myself ever justify choosing EPS foam insulation - a petroleum-based product - instead of cellulose, hemp insulation, mineral wool or wood fiber insulation? Heresy!

That is a very legitimate question, and I’m really not trying to justify my choices from decades ago, my aim here is to present a variable that is not always considered. I’m talking about the long game – the big picture and the really long game.

Were I to build again tomorrow, I would likely gravitate towards insulating my home with something like cellulose, wood fiber or hemp. But we have a lot of tomorrows coming, and there are only so many forests and so much crop space, which, as the global population grows, is continually being turned into mini-malls and subdivisions.

In North America, construction is an $11 billion dollar a year industry, so I’m talking about scale here. There is a whole lot of building going on and it isn’t going to slow down anytime soon. So is it realistic to think we can grow enough stuff to meet the needs of the built environment using only organic bio-based building products?

At the moment there is not a huge demand for alternative natural home insulation, so by all means go buy them if they're in your budget. But when we take a critical look to the future - will there be enough cellulose to insulate every house built over the next 50 years? And if we dedicate enough crop land to produce enough hemp insulation to meet that demand, how do we reconcile the soil depletion that could lead to global starvation in the future as populations continue to explode?

As a quick little tangent - a similar dilemma began decades ago with ethanol gas. Ethanol is a plant-based transportation fuel and therefore ‘eco-friendly’, right? However, when the inevitable day comes when there aren't enough plants left to feed everyone on the planet, we may conclude that growing crops to fill gas tanks instead of mouths may not have been such a smooth move afterall. So, is it not possible that we may one day think the same of our insulation, or our wood-framed structures?

Were we to fast forward into the future when there will be more people, less usable crop land, less forests, less old newspapers kicking around, which insulation could - and on a truly grand scale - meet the demands of the global building industry with the least impact? Well, it’s starting to seem like that may well be foam. Yes, I said it, and yes, we have a comments section below where I invite you to tear me a new one, but please read your way to it and don’t skip ahead!

The actual volume of raw material in EPS foam is really not that significant when you think about it, and while not perfect, the blowing agents used in manufacturing are not the worst on the market.

The current emissions of XPS (extruded polystyrene foam) manufacturing are 1430 times worse than carbon as a heat-trapping greenhouse gas, but EPS (expanded polystyrene) is only 7 times worse. And we are convinced that can be improved. Think of EPS sort of like a cousin from out of town that’s had a few minor brushes with the law, but overall they are a pretty good egg and certainly worth rehabilitating.

Foam insulation can be made more eco-friendly

How’s that for a catch phrase – eco-friendly foam insulation! I know some of you have forehead veins that are beginning to throb now, thanks for reading along so patiently.

Once we finally accept that we simply won’t have enough bio-based natural building materials to supply the demand of the global construction industry as we 'Thelma and Louise' our way towards a climate catastrophe, we need to explore options realistically. That means entertaining ideas that until now we may have considered blasphemous.

So here’s my pitch - the amount of petroleum-based raw materials in EPS foam is actually quite low, and the finished product is mostly air, or it will be at least after the tiny residual amount of pentane gas escapes. For perspective - there could be less actual oil in the foam insulation of a home than it takes to fly your family to your in-laws to argue over Thanksgiving dinner. That is a totally arbitrary and baseless statement in case you think I don’t know; maybe your in-laws live around the corner. I just like to get a little saucy when I crop-dust my fellow green builders with a contentious topic.

If we were able to find greener foam blowing agents (spray foam is already transitioning to lower GHG blowing agents; read more here), then you solve a big part of the problem. If we capture and re-use the blowing agents, like pentane gas, even better. And if we create large-scale recycling of older foam insulation to make new foam insulation, then things really start looking up. And all of those things are possible.

Another one of our bigger concerns in the past – the addition of brominated fire retardants (HBCDs) to rigid foam panels - has now mostly been phased-out by the major manufacturers.

Before you head to the comments section with a list of other flaws that surround EPS foam, we know. It may be more susceptible to termite damage that other materials. It isn't as great for soundproofing. You don’t want to be around it when a building is on fire. There is some evidence that it can shrink over time. All of that is true, but there are workarounds to all those problems.

The point is, things on the planet don’t look so great right now. And if we remove our blinders and acknowledge the true state of global affairs and the reality of how much we need to build over the next century to house untold billions of people, nothing can be left off the table if we’re going to pull out of this environmental nosedive.

There are way too many of us, and after generations of an utterly abysmal track record of natural resource management, we don’t have any more time to waste. Any solution needs to be scalable, and EPS foam insulation may well be such a solution if we continue to work to reduce its climate impact.

In conclusion – this is in no way a recommendation for you to choose foam insulation products over bio-based natural insulation, this is more as a nudge to the foam insulation manufacturers of the world – please keep cleaning up your act, we may need you in the near future. And it's also possible that there will be foam alternatives that might make it into production as an eco-friendly Styrofoam replacements soon.

This article is a shout-out to Architect, Professor, Editor, Building Scientist, Environmentalist, Mentor and Friend, Larry Hately. Nobody hates foam like Larry hates foam, so I figure if I can get him on board then we may be onto something here.

Now you know more about the impact of climate change and whether rigid foam insulation panels may be eco-friendly. Find more pages about sustainable construction below and in the EcoHome Green Building Guide pages.

Find more about green home construction and reap the benefits of a free Ecohome Network Membership here. |

What do you think about injected PUR for SIPs? is it as bad (in emissions) as XPS? I heard about some eco-based PUR from Basf. What do you think?

You have done your homework on EPS and so I don't know if I can change your mind on the "green" properties of EPS but I will make my argument. Pentane is used as a blowing agent but the insulating value does not depend on pentane as do some insulations. The moment steam is applied the pentane gas is being collected. The gas is burned off and the emissions are scrubbed before it is released to the atmosphere. The insecticide in EPS is a product called Timbor. It is not toxic to humans or pets. The Timbor is a dry powder that is dissolved in water and introduced into the expanded bead by steam. There is not a lot in each board for sure. EPS is flame resistant. It must be used with a 25 min. Fire barrier like a 5/8" drywall. It is very easy to recycle and so there is no need to take the waste to the landfill. Most manufacturers are happy to take back as it is free money for them. This is already too much for the comments but I hope it is helpful.

Very helpful actually, and very cool, Joe. thanks for taking the time to add that.

After 45 years retrofitting homes, most high performance homes use foam. Exterior panels shrink in the heat and lose their R value. Interior spray pulls away from studs as the house settles overtime. Combined foam stops drying and supports mold. The fix is ten times the cost of doing it right the first time.

My call is a 6" perimeter wall with 2x4 staggard studs and dense pack insulation of your choice. 100% thermal break, no need for exterior continuous insulation. Dries both ways. 2x4 are a little cheaper. Hope this helps.

Hi Scott, thanks for that. The last Ecohome demonstration home (the Wakefield House) was built with dense-packed cellulose. Six inches would be great for a moderately-cold climate, but where we last built in Quebec the climate is fairly harsh, so our walls were much thicker. But your assembly does address thermal bridging, and the ability to dry in both directions is a very durable design feature.

Thanks for adding that point about foam shrinking, that can be true. However, if it is ship-lapped or multiple layers with offset joints and includes a well-applied air barier, that would largely mitigate any negative effects of shrinkage.

Hi,

what about an exterior residential wall with 2" eps over 2" polyiso? Or, 2 x 2" of poyiso? The inner layes are kept warm by the outer layers and maintain their higher R value performance in colder weather.

Thanks

A

Hi Andy, you are obviously referring to the fact that Polyiso insulation loses R value in colder temperatures. What you are suggesting would certainly help mitigate that by keeping it warmer. The drop in performance when its cold isn't catastrophic but it is a consideration.

As a builder and developer of EPS foam and rolled steel homes, a product I've worked on for 44 years. The above article was the most intelligent discussion I have ever seen on the subject.

The last point of the weight of the building constructed with EPS foam versus conventional stick or block or is the key to the argument that it's a green product

I am an alternative home builder. I have built straw, bell adobe, rammed earth, Egyptian style adobe, almost every kind of alternative building method tried.

In the future, most homes will be built out of EPS, foam and steel

The current company I work with uses rolls, thin, high strain, steel cleverly folded with EPS foam Geo foam

Think about the synergy of filling a aluminum can with Foam and then trying to crush

The limit the growth said we had to do 10 times as much to have a civilization in 50 years back in the 70s EPS foam creates the same structural a stick built in the superior method

It's 100% accurate. It can be computer cut and designed the shipping weight is the 10th the heating and cooling savings is 90% and the home is made of nothing.

And truth to survive each iteration of design does the same with less until eventually something is done with nothing

This product is about halfway to that point the entire building doesn't weigh 10% of a conventional building at the stick built stage

We assemble a building in a day

The majority of the work is done in a factory

The exterior and interior coverings are conventional

The material will last indefinitely

The savings to the planet are incredible

If they were a better product, I would've dealt with it by now. Straw Bale comes close to the insulation value, but falls short on the air change.

I don't particularly like to build airtight buildings, but a foam and steel house is airtight

It's also seismic resistant because it doesn't weigh anything you can't be crushed to death under a foam house, unless you put tiles on the roof

It's pretty much fireproof because there's not enough mass to sustain combustion. It simply shrinks away from the exterior cladding and extinguishers.

It's mildew and mold resistant. I don't know anything about termites eating through the foam and steel building but termites can eat through wood so they could eat through foam and steel but there's no cellulose in it, so why would they bother and they are steel shields at the top and bottom of the plates. In general the combination of steel and foam is synergistically exceptional

Hi Marc, Thanks for taking the time to share your thoughts. We do feel that EPS will be an important part of meeting the global construction demand in as little harmful way as possible, and removing the stigma is the first step. Nothing is perfect and every construction method or material will have some sort of drawback or negative impact, it is a case of looking at them realistically for the long termn and managing the risks and impacts.

Steel has its place, but the most important thing is to not have it pass through the building envelope as a thermal bridge. Again, it is a necessary building material with limitatations on its succesful application, we just need to be aware of them.

This structurses have off set "T" studs. No thermal bridging at all. Patented system based on no thermal bridging. the Physics of this steel structure does not allow conduction when attached to the geo foam, too thin. Stucture is increased as necessary by adding additional steel "C's"... House in Phx AZ build identically to traditional stick... One was 900 a month to cool, the other 90... guess which? 40 years plus of 10% energy bills is "Affordable Housing"... the only way for profit builders can make luxury (3000 plus feet) affordable housing. $810 savings per month x 40 years is $ 388,800 in savings at current cost. Plus in Phx, 4 tons of cooling compared to 1/2 ton installed and maintained. All standard trades can sub their systems in these... Precut chases, and exact window and door openings, 1/10 assemble time.... 100% reuseable, recylable, sustainable... stronger, better homes buildt build for less that last..."forever"... What's not to revolutionize the building industry here????

The panels we use are designed without thermal bridging. Each "T"stud is offset from those on the opposite side. The thin gauge steel will not transmit heat very far in anycase. If you email me I can send you a video presentation. [email protected]