Are tiny houses a good investment? That depends on how you want to live and how well they are built. Small homes are more affordable and eco-friendly that large homes, but are tiny homes on wheels for sale locally green? Read here to find out if Tiny Houses are good for the environment.

It seems somewhat contradictory for an environmentally conscious person to be dragging a tiny home behind a massive gas-guzzling truck, even more so if it isn’t well-insulated. Small homes are good, but mobile homes, well….not so much. See here to find where it is Legal to park and live in a Tiny House.

But the most notable design limitations of tiny houses is that you have to balance interior living space with a maximum highway width of 8.5 feet. That almost always leads to poorly-insulated walls with poor energy performance. It also leads to the use of spray polyethylene foam since it has a higher R value per inch, and while spray foam works well, the problem is that most brands of spray foam insulation have high greenhouse gas emissions. Read here about how to find more environmentally-friendly spray foam with lower emissions.

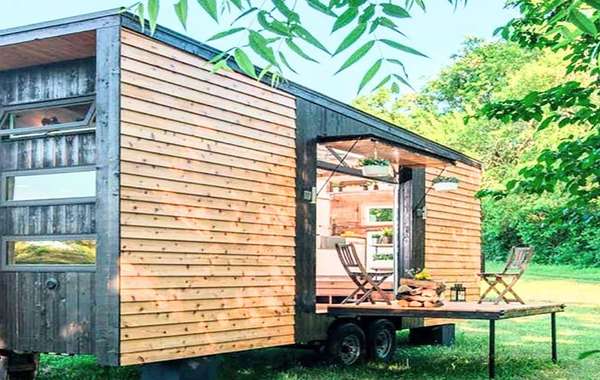

A tiny home built on a slab on grade that isn’t going to have to move is a better idea than one that does move, but the reality is that a lot people are into Tiny House living partly to be able to travel with it. Which brings us to the one built by Ben Hayward, a Carleton University Architecture grad student.

Ben has come up with a Tiny House Design that in our opinion takes a big step closer to achieving one of the main goals of the tiny house movement; namely, being 'green'.

The wall structure of Ben Hayward's 180 square foot tiny house is his own grid-like design of plywood, and is insulated with mineral wool, a recycled stone dust insulation. The wall thickness and levels of insulation vary slightly, with the weakest point of the wall being R48, which is about double that of your typical new home under construction.

Ben's Tiny House Plans:

Having done a 3D computer model of the building shape made it possible to use the CNC machine at Carleton University (computer numerical control), an automated mill that cut the plywood wall components to an accuracy of within 1 mm, and allowed pieces to be friction fit during assembly.

"With such a fine tolerance of accuracy, we were able to achieve complex curvature that would be too complicated to do in any other way", says Hayward, who goes on to compare the assembly to doing "a big 3D puzzle".

Tiny House Design

The staples of tiny house design seem to be the following - low ceilings over a narrow galley kitchen and a tiny stand-up shower (where you would be lucky to reach all the places you want to wash), over which is a loft bedroom with little-to-no head room and a ladder smack in the middle of your kitchen or living room. This is not the case with Hayward's tiny house. He has designed a double bed on a pulley system that retreats up into the ceiling in seconds, leaving behind an open living area.

On Hayward's 'to-do list' is the design of a detachable dining room table with folding legs that tucks up under the bed, so there will be an option of open living space or a table capable of seating eight people.

This clever hide-a-bed design has excellent space saving benefits, though like most things in life is not without its own drawbacks, for example - good luck retreating to bed early if a dinner party drags on longer than you'd like. It also seems less convenient if one half of a pair typically goes to bed sooner than the other, but you just can't have everything in life.

Including a retractable bed means no need for a loft sleeping area, and therefore, the higher ceilings allow for a more open and comfortable space. This also leaves room for raised floor sections under which Hayward has included drawers and even a Lazy Susan-type spinning clothes dresser.

The bathroom is not at all cramped and will have a normal-sized shower and toilet, which goes a long way towards making this house seem a realistic option for long term living.

A triple-pane sliding patio door means a lot of natural light, as well as passive heat collection when parked facing south. This will reduce the burden on the solar panel heating system.

How to Insulate and Heat a Tiny House

Energy and performance of Ben Hayward's Tiny House

- R-48+ walls

- Floors ranging from R-42 to R-120 under the bathroom

- Triple-pane sliding patio door

- Photovoltaic panels and a wind turbine will power two hot water tanks for radiant heating and domestic hot water

- Walls, as well as floors, will be heated with radiant tubing

Read more here about Portable Wind Generators and Micro Power Generation.

The grid of plywood that forms the walls will certainly not make for the easiest of insulation jobs (as every batt and rigid board will need to be cut), so it's not something we would want to undertake for a conventional house, but for a small job like this it seems manageable.

This unusual wall design does stands out from most other tiny houses we've seen in one seriously green way - recyclability during its inevitable deconstruction. Building materials that have been spray-foamed have only one foreseeable resting place in their future, a land fill. This house on the other hand, looks to be easily disassembled and recyclable at the end of its life.

In meeting Ben Hayward for a tour of his build, which he describes as a 'research project', one thing became apparent - he is not someone married to his ideas if better ones show up. Having the good sense to adapt along the way when it make sense is the hallmark of a good designer/builder, and allows for the freedom to push the envelope and try new things without an ego to protect if an idea turns out to be a dud.

This project is Hayward's second such build. He says much of the design is an evolution of his previous tiny house titled the 'Hobbit Van', which received widespread attention in North America, including a feature in the Wall Street Journal. You can see that project unfold in the YouTube video at the bottom of the page and follow this build on Ben's Instagram.

All photos and computer renderings courtesy of Ben Hayward

|

|

|

|

|

|

Below is a Tiny House construction video of Ben's first design, the 'Hobbit House'.

Useful tips! Building your own tiny home can morph into a REALLY expensive project if you don't know what can go wrong.