Not all insulation materials are the same, and they are not always interchangeable

A basic understanding of how walls work is needed to help you understand what you can reasonably expect insulation and building materials to do for you when they are part of a wall assembly. If you have a working knowledge of building science then forge ahead, if not, check out this video about high-performance wall construction and insulation first to learn the basics.

Understanding the physics behind how walls work is the key to designing well-insulated, airtight and durable wall systems.

Loose fill or dense-packed cellulose insulation

Recycled Content: 80% to 100%

-

Method and form: Cellulose consists of shredded newsprint and is non-toxic, recycled and generally local. It’s great for attics, you can blow it to whatever depth you want (with proper ventilation) and there are no seams to allow heat loss. It’s also an excellent choice for insulation packed into walls because it allows little air infiltration and it’s fire and insect resistant.

-

R value: 3.66 per inch

-

Notes: All around this is the best choice for performance and environmental impact, but not recommended for basements due to its sensitivity to moisture.

Cellulose rigid foam panel insulation

UPDATE: A new environmentally-friendly rigid foam insulation board made from cellulose nanocrystals is a viable alternative to Styrofoam - according to researchers at WSU...

This product has us really excited, because it's looking like a "game-changer" though it is still in the research stage and not yet commercially available, it deserves a mention. Researchers at Washington State University have developed a rigid cellulose foam insulation panel that one day we hope will replace plastics based foam as a standard building insulation. And better still is when the natural alternative for these plastic based rigid foam insulation boards is a naturally derived cellulose high-performance panel with a higher R-value than current rigid insulation panels such as EPS, XPS and Styrofoam. Read more about which are the best rigid cellulose foam insulation panels here

Fibreglass insulation

Recycled Content: About 20%

-

Method and form: Batts are most common but it’s available in rigid. Reasonably low impact in production; raw materials are abundant; it offers good R value and reasonably good soundproofing.

R value: 2.9 - 3.8 per inch

-

Notes: Fibres are volatile and installation can irritate the skin. Be sure to wear a mask, gloves and goggles. Make sure it is well installed- It doesn’t perform well if compressed, and gaps around studs and headers can actually encourage air convection causing heat loss.

-

Fibreglass is moisture sensitive and should not be installed where it will be exposed to moisture. Despite how commonly it can be found insulating foundation walls, it should never be installed against a cold concrete wall. See our pages on how to avoid or get rid of mold in basements for more on this.

Rockwool mineral fiber insulation:

Recycled Content: there is a minimum of 75% industrial waste in stone wool insulation, often as high as 90%. The most common commercial manufacturer is Roxul, so that tends to be its common name on job sites.

-

Method and form: Batts or rigid panels, the batts are an excellent replacement for fiberglass (as seen in the main image above). Rock wool can be more costly per batt but has a higher R value than fibreglass per inch; less health risks during installation; easier installation; it performs better for fire and sound and is less harmful to the environment. Rock wool ComfortBoard rigid board insulation comes in various thicknesses starting at 1 ¼ (R5). Installed in conjunction with batts it can be a great replacement for foam as a thermal break.

-

Rock wool batts can be either specifically designed for insulation, or specifically designed for soundproofing. Insulation batts are not rated for soundproofing, but still outperform most other materials for sound reduction. Be sure to get the right product for the right application.

-

Rock wool in interior walls reduces sound between rooms and floors, as well as offering fire protection.

-

Below grade durability : as the climate warms, termites are moving north into Canada. Termites love foam insulation but the fibers in rock wool cut them, so they leave it alone.

Note: Rockwool insulation is a favourite of ours because of its durability and versatility. It is completely permeable to and unharmed by moisture, so there is less risk of damage during installation as well as during its operational life. It is hydrophobic (meaning it will not absorb water and moisture), so it can get wet without causing great concern. Once it dries it will maintain it's original R value. Given the chronic water and humidity problems that plague basements, stone wool is a much more suitable product for basement wall insulation than fiberglass.

Hemp insulation:

Recycled content: Hemp is a natural and renewable material, making hemp batt insulation (and hemp boards) a very sustainable building material. As it is a newly emerging raw building material, no market for recycled materials has formed, but the materials are recycleable and reusable. Read more about hemp insulation.

R value of Hemp: about R3.5 per inch.

Pros: Hemp acts as carbon storage, it is renewable and non-toxic. Hemp batts handle moisture quite well, and can safely absorb moisture contained in framing materials making it a durable form of batt insulation. It works to reduce sound transmission and is resistant to insects and pests. Hemp is Hypoallergenic and natural so no special safety gear such as gloves or masks are required during installation and it can help ensure a home with extremely safe and clean air quality.

Cons: It’s not a cheap material just yet, but hopefully that will change as it earns a larger market share in the mainstream industry. Expect to pay a little more than Rockwool panels.

Hemp doesn’t compress well, so it takes more volume for shipping. It can be tough to cut, so when purchasing Hemp insulation it is recommended to purchase a saw at the same time.

Straw bale homes:

Recycled Content: Straw bale walls are the used stalks of grains, so they are generally 100% recycled and act as carbon storage so this will significantly reduce the overall ecological impact of your home.

-

Method and form: Traditionally it’s been done as stacked bale walls that are then covered in mud, and now prefab straw panels are beginning to show up on the market. You won’t find them at the big box stores, but they’re out there. A Green home in Peterborough, Ontario will be using them in an attempt to be the greenest home construction in Canada, success of that project will likely earn straw panels a bit exposure.

-

Notes: Be sure to research techniques well, being an organic material straw bales are highly susceptible to moisture damage and must be kept completely dry during construction. We really want to stress this, because this is a sensitive building technique and the stakes are pretty high if you don't do it right.

-

Bale walls have a very high R-value (around R40) and make for about as environmentally responsible a building material as you can get. But it is extremely labour intensive for sealing, so hopefully you have lots of friends that like playing with mud.

-

Excellent for soundproofing

Foam boards: expanded (EPS) vs. extruded (XPS)

XPS (Extruded polystyrene) refers to the coloured solid foam panels you most often see on the outside of buildings under construction. It offers a higher density and higher R-value per inch than EPS (expanded polystyrene) but because of its lower cost, EPS offers more R-value per dollar spent.

Manufacturers of XPS and EPS claim both products can be recycled, but a complete life cycle analysis shows EPS having a better overall environmental impact when compared to XPS, as EPS can be recycled in many more ways at the end of its usefulness. Read more about rigid foam insulation panel choices here.

Expanded polystyrene foam (EPS)

Recycled content: Not very high, (though it could and should be, but it isn't commercially viable.)

-

Method and form: Comes in panels, 2x8, 4x8 and other dimensions, with variable thicknesses.

-

R value: 3.6 to 4.2 per inch.

-

Notes: EPS is the only commercially available foam insulation panel that is at all vapour permeable, which can be an advantage in some applications, as can those that are vapour impermeable.

The common blowing agent for EPS is pentane gas, which is ozone safe but has a global warming potential (GWP) 7 times greater than carbon dioxide. This is significantly lower than other types of foam, so we recommend it as the preferred choice of foam whenever foam insulation is the best option possible for the application.

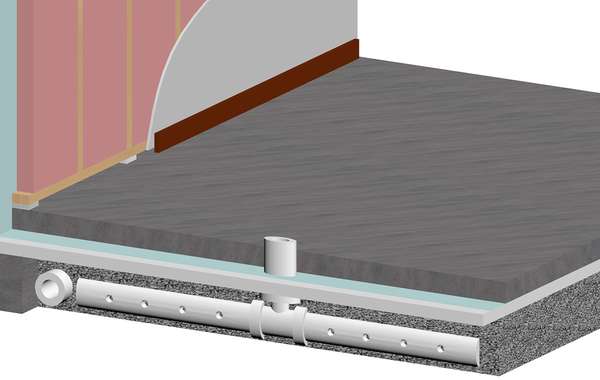

Excellent as a rigid foam insulation board for below grade applications and insulated slab forming, both inside and out. EPS is unharmed by moisture, and allows a certain amount of moisture to pass through it. Even Treehugger recently admitted that in certain applications, such as remedial wall insulation, EPS foam insulation needs to "come out of the shadows" of being lumped in with Styrofoam as it makes absolutely the best sense per $ and environmentally for continuous and resistant insulation in buildings.

Extruded Polystyrene Foam (XPS)

Recycled content: Minimal at best.

-

Method and form: Comes in panels, 2x8, 4x8 and other dimensions.

-

R value: 5 per inch

-

Notes:

XPS acts as a vapour barrier and air barrier.

Blowing agents are 1430 times worse than carbon dioxide, exponentially worse than EPS. For ecological reasons rather than performance, we recommend limiting its use when possible unless it is genuine Dow Corning styrofoam which uses foam blowing agents that are environmentally better. All the same, a combination of polyethylene and EPS can offer the same vapour protection as XPS, more affordably and with significantly less impact on climate.

XPS is durable and unharmed by moisture, so it works well below grade, but not as well as EPS because of long-term moisture retention.

S.PU.F. (Spray Polyurethane Foam)

Update: new blowing agents for spray foam dramatically reduce their environmental impact. Read more.

Recycled Content: Minimal at best. Some are advertised as ‘soy based’ but there is so little soy content compared to the ecological impacts, that it borders on green-washing. Use it for its excellent properties, but don’t fool yourself into thinking your home is insulated with tofu, because it most definitely is not.

-

Method and form: Urethane is sprayed on, and structurally solid to the point that you can walk on it in about 20 minutes.

-

R value: 6 per inch

-

Notes: SPUF acts as a vapour barrier and air barrier; blowing agents are also much worse than carbon dioxide and EPS. Off-gasing can be an even greater concern than other products as chemicals are mixed onsite, so no off-gasing takes place in manufacturing facilites and different stages of transit, but rather all in your home.

Polyisocyanurate insulation (or Polyiso)

Method and form: commonly in 2x8 or 4x8 sheets with foil backing

Performance: R6 - 6.5 and even higher are the claims of some producers, but independent researchers say it is more accurately calculated at about R5.6 per inch. Read more here about the potential pitfalls of polyiso insulation.

Polyiso can be a great product in some applications but has some notable limitations. It is moisture sensitive, so it is important that it not be exposed to weather during construction or its service life. Panels come with foil membranes on either side to contain gas, though it will leak out eventually, reducing R values.

The stated performance is R6 - 6.5 per inch, but this is somewhat misleading as that is only at warmer temperatures. The performance starts to drop significantly below 10°C, and its performance at much lower temperatures (-20°C and below) is abysmal, hardly better than wood. A great product for interior use, but it must be on the warmer side of a wall assembly to do any good at all.

In the right environment (warm and dry) polyiso is one of the preferred foam products as the performance is high but the GWP is low, similar to that of EPS. Be aware that the foil membrane acts as a vapour barrier, and taped can act as an air barrier as well.

Cotton insulation (denim)

-

Recycled Content: 90-100% recycled. Use your GWG’s to lower your GHG’s

-

Method and form: It comes in batt form like fibreglass and stone wool. It performs better than fiberglass during high winds and at low temperatures; it is extremely effective for sound absorption and thermal performance; easier installation than fibreglass; no protective gear needed; it contains 10% boron-based fire retardant (a natural non-toxic mineral),and it's resistant to fungus, mold, and pests.

-

R value: 3.4-3.7 per inch

- Notes: It takes less energy to manufacture than other types of traditional insulation, contains no chemical irritants, and is completely safe and easy to install by homeowners. It’s not too common in the Canadian market yet, so it might be expensive if your lucky enough to even find it.

Thermal foil vapor barrier:

We’re including this with insulation, mostly to make clear its proper applications. Thermal foil refers to a bubble wrap with foil that acts to reflect infrared heat in certain situations. For it to work properly there needs to be an air space on the warm side.

It is an effective (if expensive) vapor barrier, and if you install a second layer of strapping for an air space, it will reduce infrared heat loss. Exactly how much is hotly debated and depends a a couple of factors - how it is installed and where it is installed within the wall assembly. Whether or not you will get your money out of it is questionable.

The place NOT to use it is anywhere that it will have no air space, like underneath a concrete basement floor as insulation. I say this because it has been used for this purpose, and is completely ineffective. It would do no harm and still work as a vapour barrier, but it is a waste of money buried in concrete. See our pages on the best amount of basement slab insulation for more on how best to stay warm below grade.

To read about every aspect of insulation choices and applications when building or renovating a high performance home to a better standard for the dollars spent see here, from the EcoHome Green Building Guides - North America's best green building resource...

To watch 'how to' videos about insulating a Living Green Roof see here

Great Insulation imformation. I really like the Cotton/Denim

Yes it is a little more money than the toxic itchy mold growing other stuff but you get what you pay for. After 25 years in the drywall and insulation business I liked it so much I opened my company to create availability in central and eastern Canada. Keep up the GREAT work

Kevin Royce / ECO Building Resource

Thanks for the feedback Kevin. Feel free to include your contact info so people can find you as well.

And if you're interested in sharing more about this product contact me and maybe we can add something more detailed to the page regarding the benefits, performance and cost. [email protected]

Regards,

Mike

Have you investigated Icynene spray foam insulation as an alternative to the standard polyurethane foam mentioned above? Apparently it is made from castor oil, has no VOCs and uses water for expansion while applying, instead of HFC's or HCFC's.

Kevin, I have read that the cotton batts are difficult to cut and do not expand to fill gaps as well as other types of batt insulation. I am a designer, not an installer, so I'd like to hear your take on these comments from others.

Thanks, Greg.

Hi, I have a cottage built in 1960 and need to insulate it. I am not sure if I should apply insulation inside or outside. Foundation: cement, walls: brick in the lower part and then wood further up. Who can help me with this project?

thank you so much.

Hi, certainly its essential to insulate outside of building however sometimes it is not so easy or even impossible due specific circumstances as facade detailing you want to keep etc

A customer asked me once.....if the blown insulation is made from newsprint...how did it become fire resistant?

It's usually treated with boric acid as a fire retardant, there are really no health effects, we often hear that it is not more harmful than table salt.

Regards.

The website that sent me here, to your excellent article, says that boric acid is actually harmful to breathe so it should be on the other side of a good barrier. I have used recycled cellulose as dense pack and loose fill insulation. It's always important to wear breathing protection, a good double-strap mask or better, when installing.

Useful info.

I think there is some info missing from this article? The last paragraph under spray foam appears to be a repeat of the XPS section.

What about expanded cork panels? Are they better for low frequency noise as compared to wool?

I don't see wool insulation here and have been looking into it for my own potential build from a company called Havelock Wool. Curious if you have any recent experience with it?

One person on our team has worked with it, and his recounting - which does echo the experience a lot of people have had with it- it is that in humid and rainy weather a home can start to smell like a sheep barn. So it most certainly is a natural and low-impact material, that one aspect keeps us from really advocating for it. If you do end up going for it and it works out fine please let us know.

Surprised to see that wood fiber insulation hasn't received much coverage here as well. Would be curious to hear your thoughts.